Abutment Screw Gets Stuck: How to Prevent This?

Dr. R. asks:

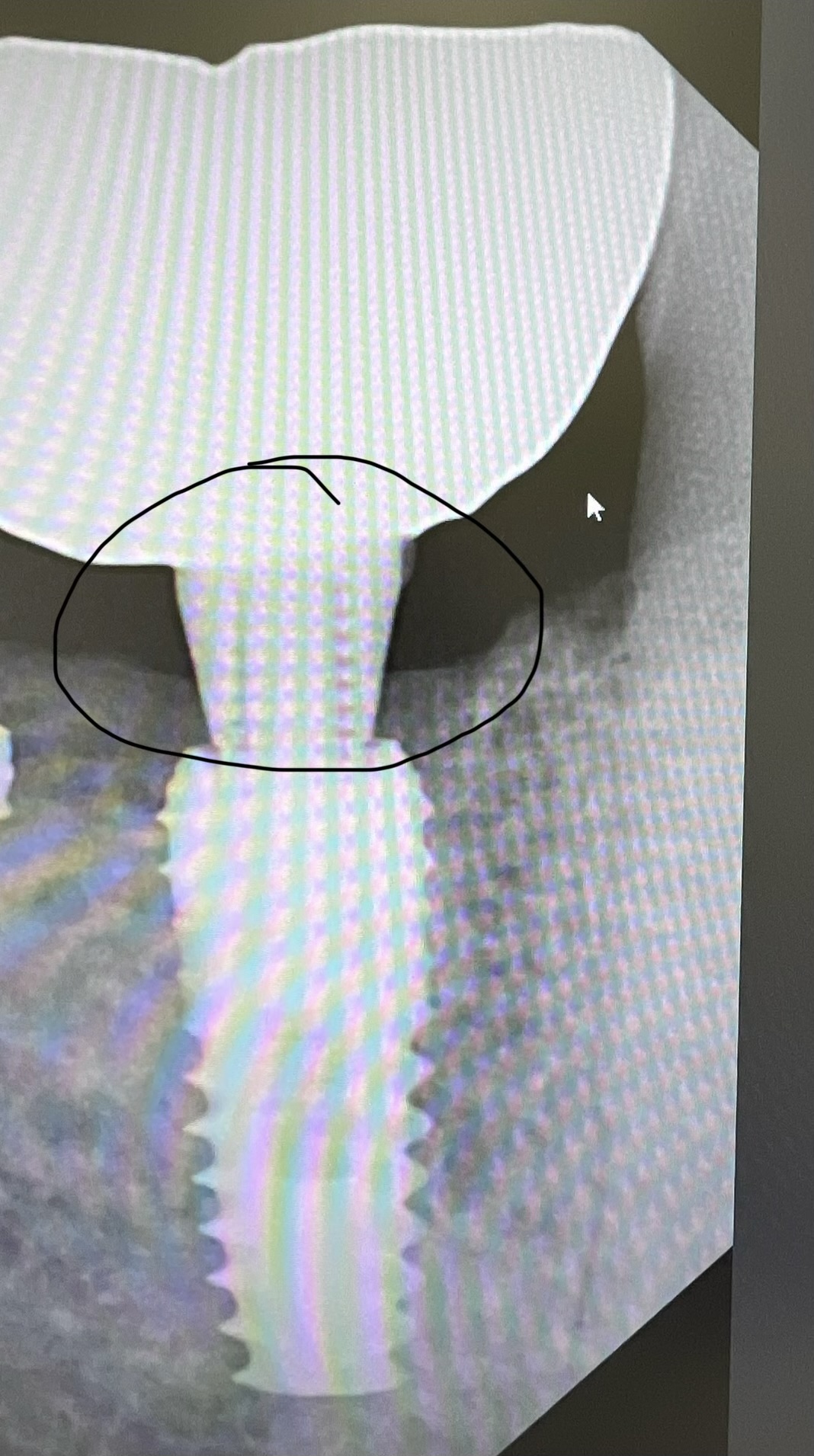

I am a general practitioner and I do not surgically place my implants. I just restore them. Last week I was screwing down the abutment screw when it got stuck. I am not sure what happened. I managed to free the screw after repeated efforts to tighten and untighten the screw. What did I do wrong? How can I prevent this from happening again? What should I do if I cannot get the abutment screw torques all the way down or if it gets stuck? Has this ever happened to any of you out there and what did you do?

16 Comments on Abutment Screw Gets Stuck: How to Prevent This?

New comments are currently closed for this post.

satish joshi

6/23/2008

Main reason for your problem could be improper alignment of screw in implant body,if parts are compatible.You can use little topical gel to lubricate your screw.

You have to be very careful in playing with implant and screw,because if you mess up threads of implant,either you have to re thread it with special threader or make custom post for cementation or condemn the implant.

charles Schlesinger, DDS

6/24/2008

I agree with Dr. Joshi- it sounds like you may have cross threaded the abutment screw. Be careful when placing these tiny screws- the threads are very fine and it does not take much to have them thread "off-angle". I lubricate my screws with a little topical antibiotic ointment like neosporin or bacitracin. It will lubricate and it can't hurt to have a little bacterial killing ability too.

Frank Strauss

6/24/2008

Since screw torque is such a critical factor, is there any concern that a screw lubricant could affect it?

Dr. Gerald Rudick

6/24/2008

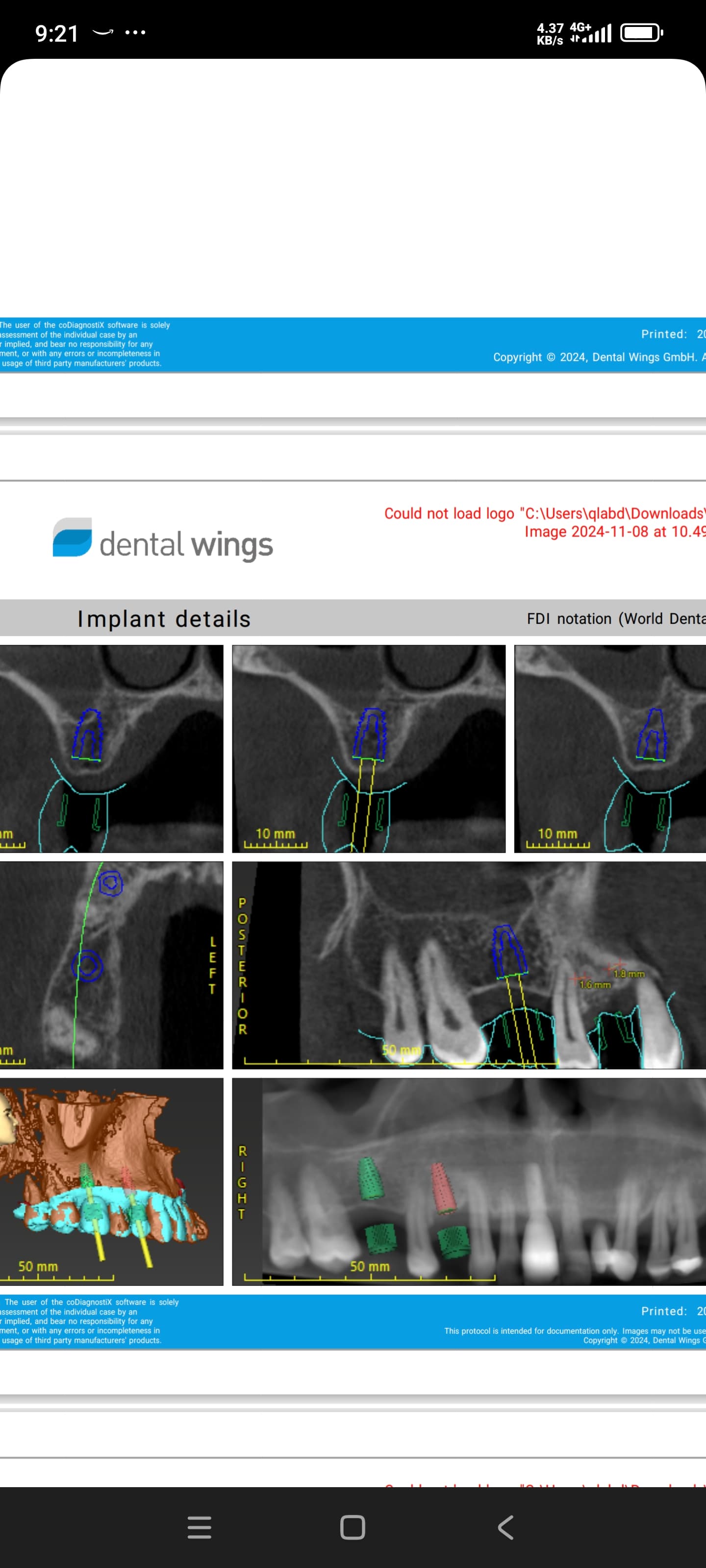

There are so many companies that manufacture implants, and so many more companies that manufacture prosthetic parts.

If you do not as yet do the surgery, then ask the surgeon not only for the name of the implant, but also the lot number. Styles and models rapidly change, and so do the parts.

Get comfortable with working with implants, take courses, learn to do the surgery, and then find a manufacturer you are comfortable with, and use that system, so you won't have any more mating problems.

Gerald Rudick dds Montreal

Carlos MartÃnez Reding

6/24/2008

I always start counter clokwise and when I´m sure that it is correctly aligned then rotate clockwise, and if a feel any resistance inmidiatly stop.

This happend very often because the surgeon is the one that start the problem when the screws is badly aligned.

You can feel it at the moment you unscrew the cover screw.

Dr.Udhayaraja.M.D.S

6/25/2008

One of the reasons is overtightening of the screw apart from wrong thread. Second could be the presence of blood in the screw and normally a good hand tightening is good enough with the cover screws

Daniel J Kim, DDS

6/25/2008

Make sure you have the correct angulation (i.e. parallel to the implant fixture). This is the most common error since the implant fixture may not be in exact alignment with the abutment/crown. Then, before tightening turn the screw counterclockwise with light pressure until you feel a "click" where the beginning of the threads (of screw and implant fixture) will just pass each other. Then you can begin to tighten and knowing the threads will engage correctly. If you tighten with the wrong angulation or when the threads are not engaged properly it will strip the threads. This is not any different than any other "nut & bolt" hardware.

MD Hume

6/25/2008

A good rule of thumb is, if you ever have a screw problem - throw it away and get a new one. Implants fracture and so do screws no matter if it is operator error or not. If the threads are stripped or worn it will loosen over time and cause another problem. Throw it away , order a new one and save yourself a headache.

Harold Bergman

6/25/2008

Sounds like you cross threaded the screw when inserting it. That is a problem with the design of the mating surface of some implant systems. Cross threading is virtually impossible with an implant designed with a Morse taper mating surface such as the Simpler One Stop, Ankyloss or Osseotite. There are a lot of other advantages to the Morse Taper as well including elimination of the potential "dead space" microgap at the mating surface .

eric wallace

6/28/2008

as a surgeon with a minor in micro-biology, i applaud the use of anti-microbial in the implant body. i would use metro-gel - metroniadozole gel- a tube will last forever and the coverage spectrum is correct. I routinely use it to fill the implant body before connecting a cover screw, healing or final abutment. it's a great lubricant for inserting screws.

regarding the screw problem, i aggree with all above. I would call the manufacturer and ask them to send you a new screw. of course, check the lot number of the fixture and abutment to check for compatibility. no muscle here please.

Dr. Ben Eby

7/1/2008

If I am careful about not cross threading the screw and I still meet resistance while screwing in the abutment, I follow a procedure before tightening down the screw to the point of no return. Simply, I check it in another implant analog. Occasionally a screw is manufactured poorly, or gets cross threaded in the lab. If you check the abutment screw by screwing it into a different, but same type implant analog, this may help. You may need a different screw.

Gary D Kitzis, DMD

7/2/2008

Slightly tongue in cheek, but I mean it: High school courses in wood and metal shop or similar experiences should be requirements for performing dental implant procedures. Having taken apart and reassembled bicycles and lawn mower carburetors is also helpful in learning to handle implant parts. I am always more than a little worried when I hear residents and practicing dentists thinking out loud "righty tighty, lefty loosey." :-)

Bob

7/3/2008

Rule of thumb: Always buy two screws, One for working in the lab with the technician and one for fitting in the patient, this is critical. As when the technician is making the crown, fine metal particles can get between the thread pitch in the screw and prevent the screw from being torqued correctly. Therefore, it is paramount that a new screw is always used for the patient. This should rule out the problem of cross threading. Always remember a screw should not be torqued more than twice, if unsure always replace it, as they are not expensive.

Gary D Kitzis, DMD

7/3/2008

Note to Bob:

I'm with you on the use of separate lab and patient prosthetic screws.

Do you have a reference in any industry (or dentistry) stating that a screw should not be brought to its working torque more than twice??? I am interested in a reference with numerical data, not an anecdotal "I think two times is it...." . I specifically mean being brought to working torque, NOT being brought up to working torque, placed into service, then removed, replaced into service .... and so on.

Dr. Bill Woods

7/6/2008

I think the use of two screws is a safe, rational and reasonable protocol that I plan to start at once. It never really occured to me to practice that but it is sound. Good Idea. Bill

Dr SDJ

8/26/2008

Dr Kitzis I don't get your question? What do mean?