Atlantis Abutments

Dr. Croll asks us:

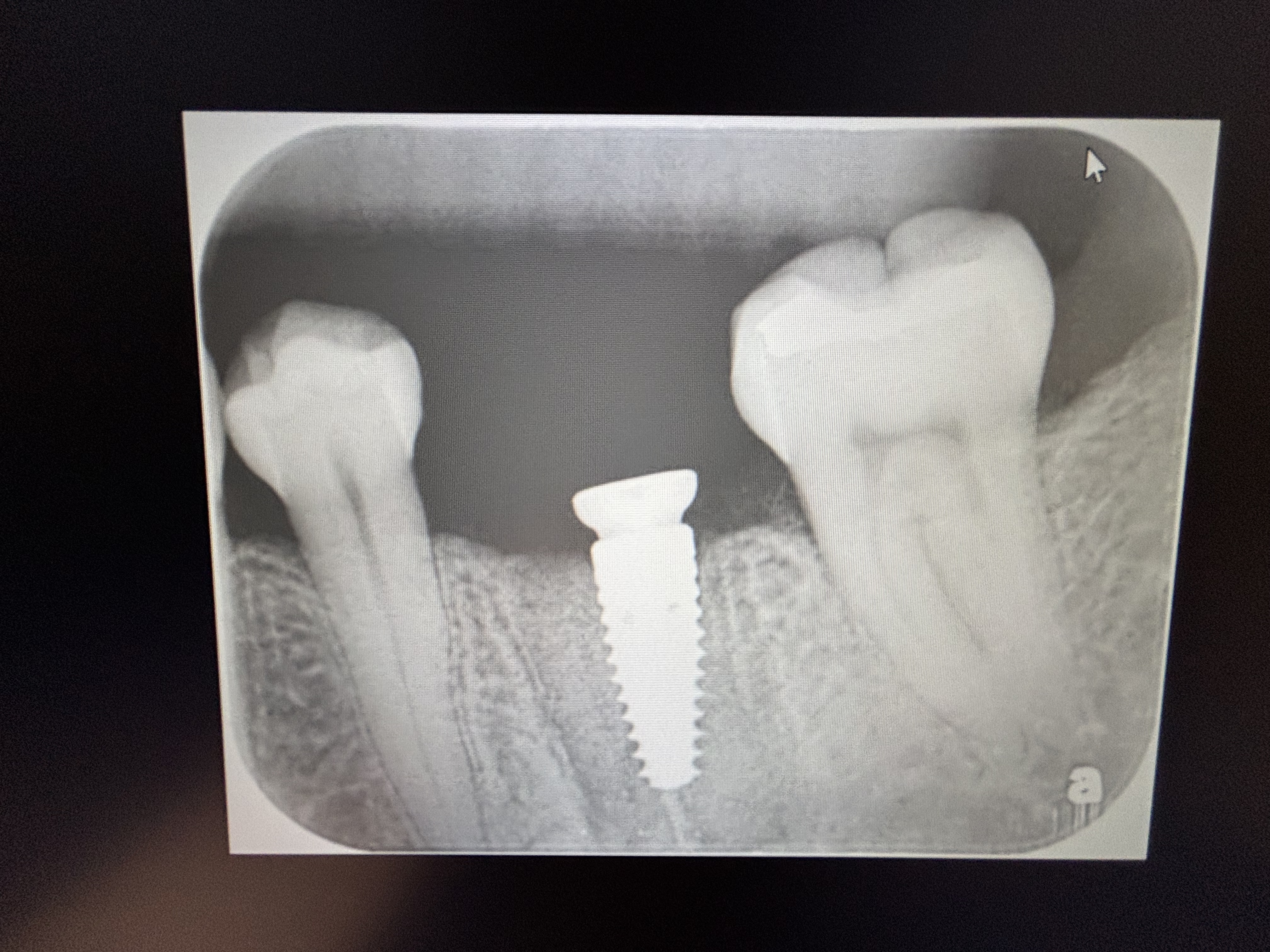

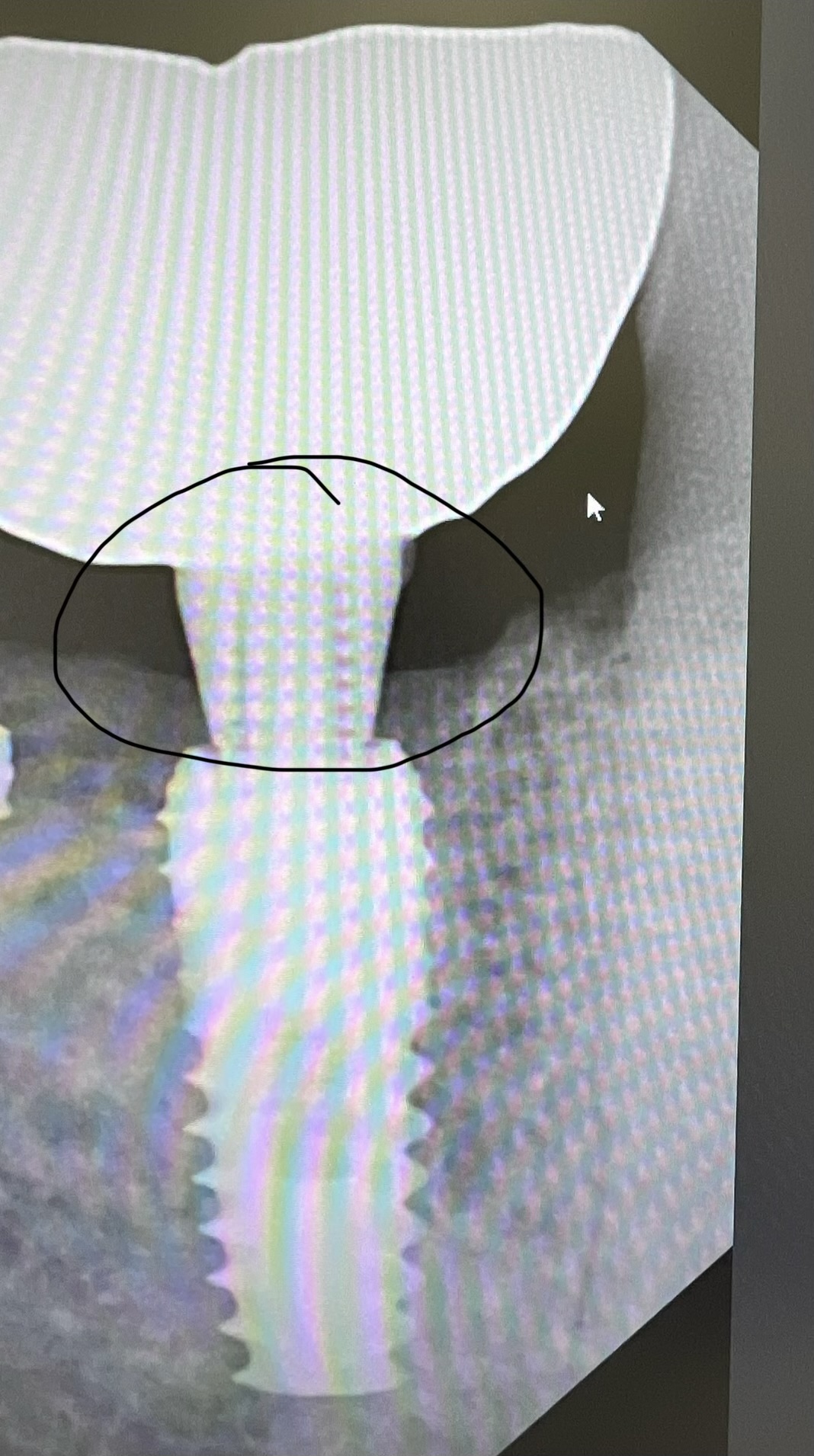

I use Atlantis custom abutments for cement retained crowns and bridges and usually the fit on single units is excellent.

Occasionally for multiple units I have found the fit of bridges to be a little tight. Are any of you using die relief to create space for the cement? I am thinking of telling my lab to use 6 coats of die spacer. Has anybody tried this already?

4 Comments on Atlantis Abutments

New comments are currently closed for this post.

Ira Dickerman

2/28/2006

We have also found that multiple unit implant restorations tend to get "tight" espefcially after ceramic application. We have taken to routinely relieving the inside of our frameworks after fit confirmation by the Dr. If done before and it needs to be sectioned the dr may feel that it fits too loose. This is not a function of Atlantis Abutments, but all cemented multiple unit implant restorations. The longer the abutments, the greater the issues.

James Biron

3/1/2006

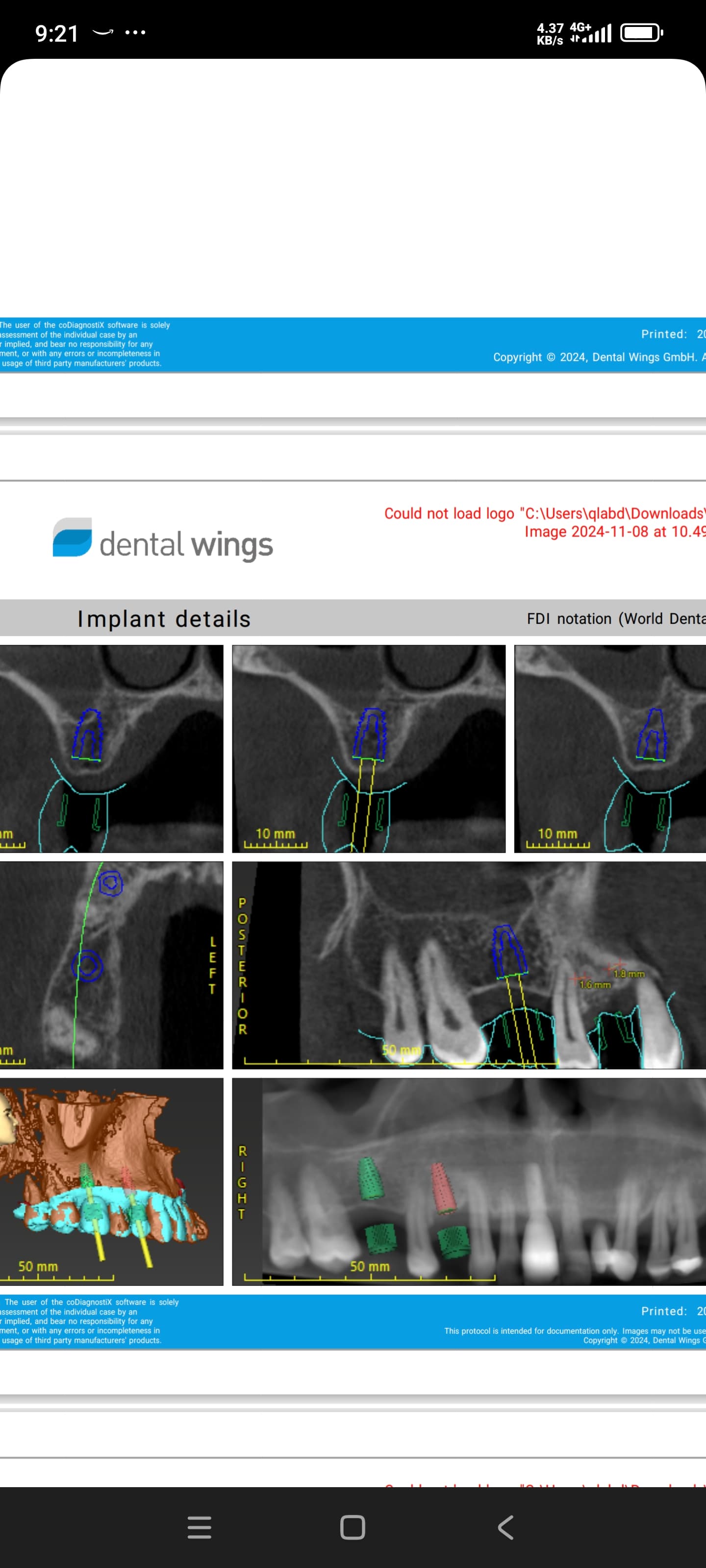

I am from Atlantis, and would like to provide input on this topic. For customers that feel that their bridges fit a little tight, we recommend that they request a five or six degree taper as a first solution. This will eliminate time in the lab applying die spacer and is easier and quicker than having to apply six coats of die spacer. Atlantis can make this adjustment with a click of a button for any degree of taper. Just note on your prescription form under "Special Instructions".

Scott D. Ganz, DMD

3/2/2006

Glad to see James from Atlantis taking the lead on this... one of the reasons why this technology (Atlantis abutments) is so innovative is that the software can make changes to the stock default design parameters as per the clinician or lab's CDT request.

When doing long spans, the accuracy is so good, and the abutments so parallel, that the frameworks will fit tightly. (Of course this assumes that the implants are reasonably placed). The easiest solution is what James has stated - change the default design settings, and adjust the taper of the abutments... on the Rx.. to the lab or Atlantis. The object here is to REDUCE chair and lab time... and this technology is expert at accomplishing both. Do not modify the metal, or add die spacer if it can be modified first in the design process.

Jon B

5/31/2010

Taper can help but the expansion of the die stone used to pour the model must be accounted for. It is good practice to match the die stone expansion to the impression material contraction. A very low expansion die stone is recomended for implant work. The accuracy of the frame work and the compression from the veneer porcelains need to be managed. In addition the interior of the copings must be checked for casting bubbles or fired porcelain.

Natural roots will drift into a slighly off bridge, ligaments will allow this, implants will not drift and need a dead passive fit. There should be room for cement allowed in the framework design along with the passsive fit. A separator like Micro Peel or rubber sep is nice for implants as it can be peeled off easily after a waxup is done.