I began treating essentially the same patient two years ago. I repaired his dentures perhaps a dozen repairs in the first six months. One time, just after delivering a hard reline, he clenched down as hard as he could to show me that he could fracture it again. The other problem he had is that he would wear out the inserts within two weeks. There was nothing wrong with the prosthetics, the flange had adequate thickness and they had adequate vertical dimension. He simply has a ferocious bite, is a bruxer and refuses to take them out at night.

Ultimately, I made him a new set of dentures with a metal framework. When they arrived from the lab I immediately returned them and asked that the thickness of the buccal flange be doubled to provide additional stability. I delivered them with 8 white (5 lb) inserts (only he can take it in and out) and it took him 8 months to fracture the acrylic and break out the front four teeth, so I have declared it a victory.

Most hints have been listed previously, here are a few that I learned with him:

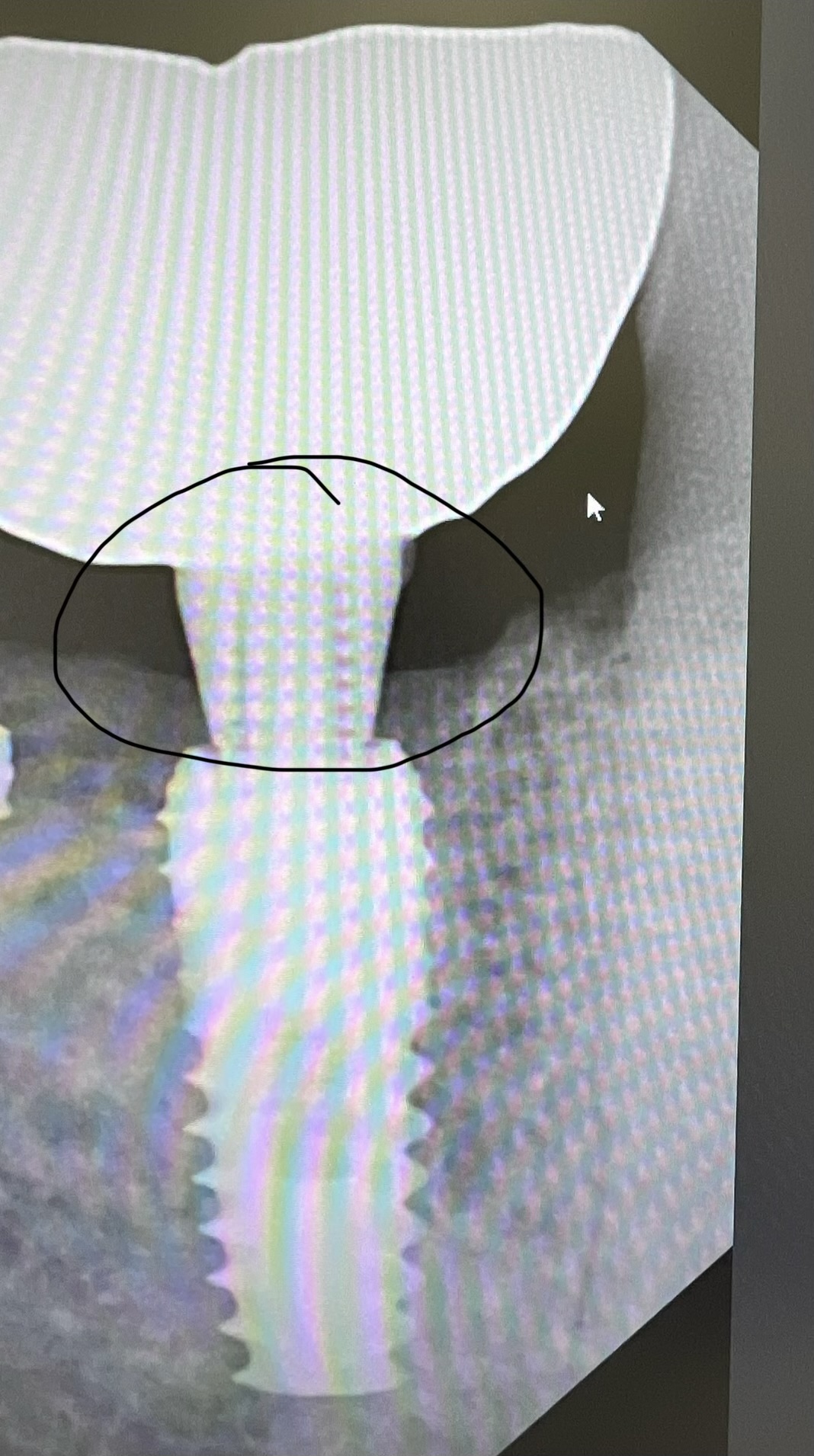

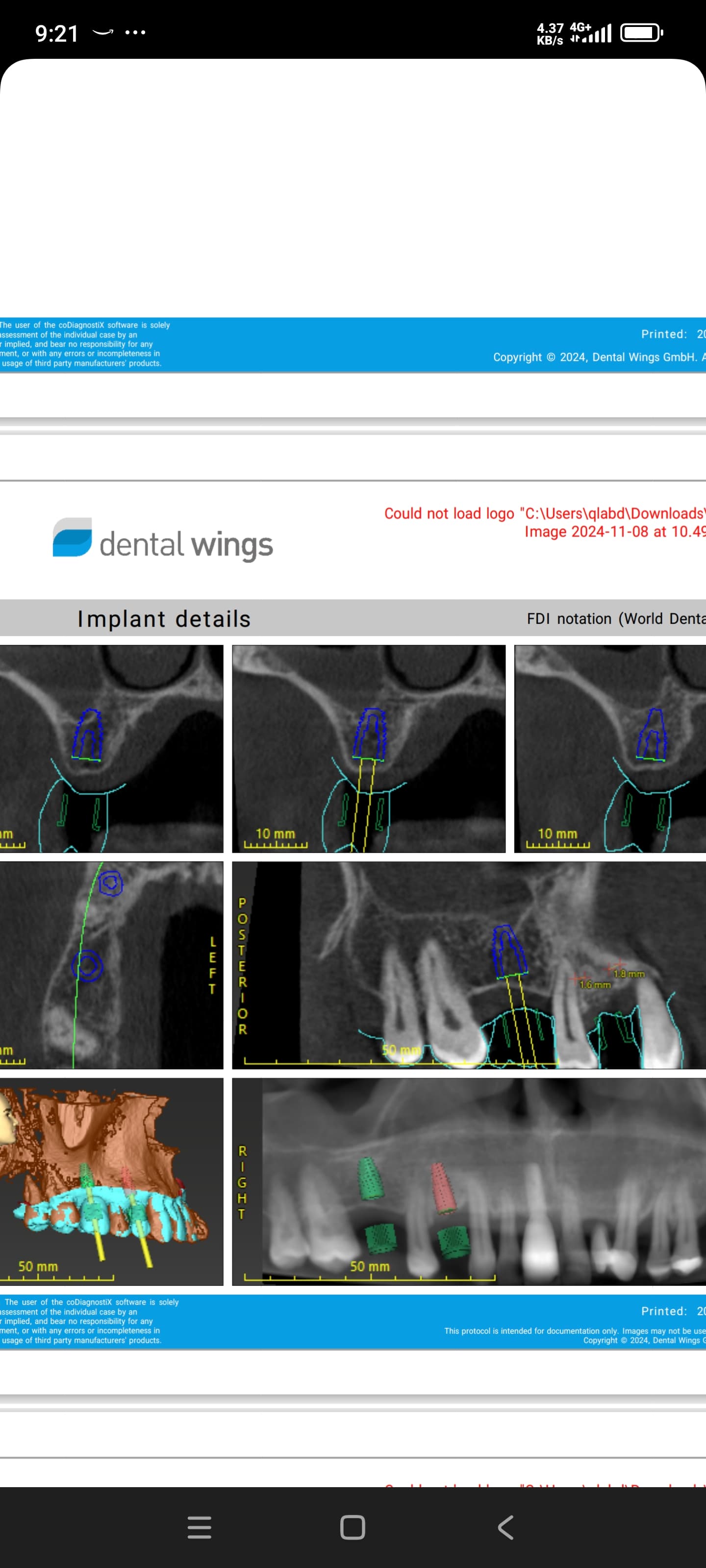

1) I corrected the divergence of the upper implants by replacing the Locator abutments with angled GPS abutments from Implant Direct (I still use Locator housings and inserts). They are now within 5 degrees and the inserts now wear normally.

2) I only use cold cure acrylic when picking up his housings. Some products are advertised for that purpose, but do not bond to the denture base (they stay in place either with an adhesive or mechanical retention). That results in a weak point where the denture can fracture.

3) When picking up housings, I personally hold the denture in place with light finger pressure for a full 11 minutes. I no longer trust patients to "close down lightly and don't move."

4) I adjust the occlusion after the housings have been picked up and the inserts are in place.

5) I added a ribbon in the upper last time it was repaired, but I have no way of quantifying if that has strengthened it.

I understand the frustration of having a patient walk in once a week with a fractured denture in hand expecting that it be repaired immediately. Best of luck, that's how I did it.