Implant screw loosening…. Loctite?

Quite a while back I remember a lecturer mentioning a product that acts as an implant screw “loctite”, to reduce the incidence of screw loosening. I can’t remember the name. Anyone know of such a product?

8 Comments on Implant screw loosening…. Loctite?

New comments are currently closed for this post.

Vladi Dvoyris

2/18/2019

Yep. Henkel Loctite 4061 (and it's approved for medical use too). You only need a very small amount, as it is quite viscous.

However, if you experience repeated screw loosening in a restorative work, it's a symptom of a mechanical problem. Thus, strengthening the screw with Loctite may help keep that specific screw in place, but the mechanical problem won't go away, and it's only a matter of time until it appears elsewhere.

Sean Rayment

2/18/2019

Dr. Christensen recommended Ceka Bond by Preat if you don't want to use Loctite. Here is a link to his article

mpedds

2/18/2019

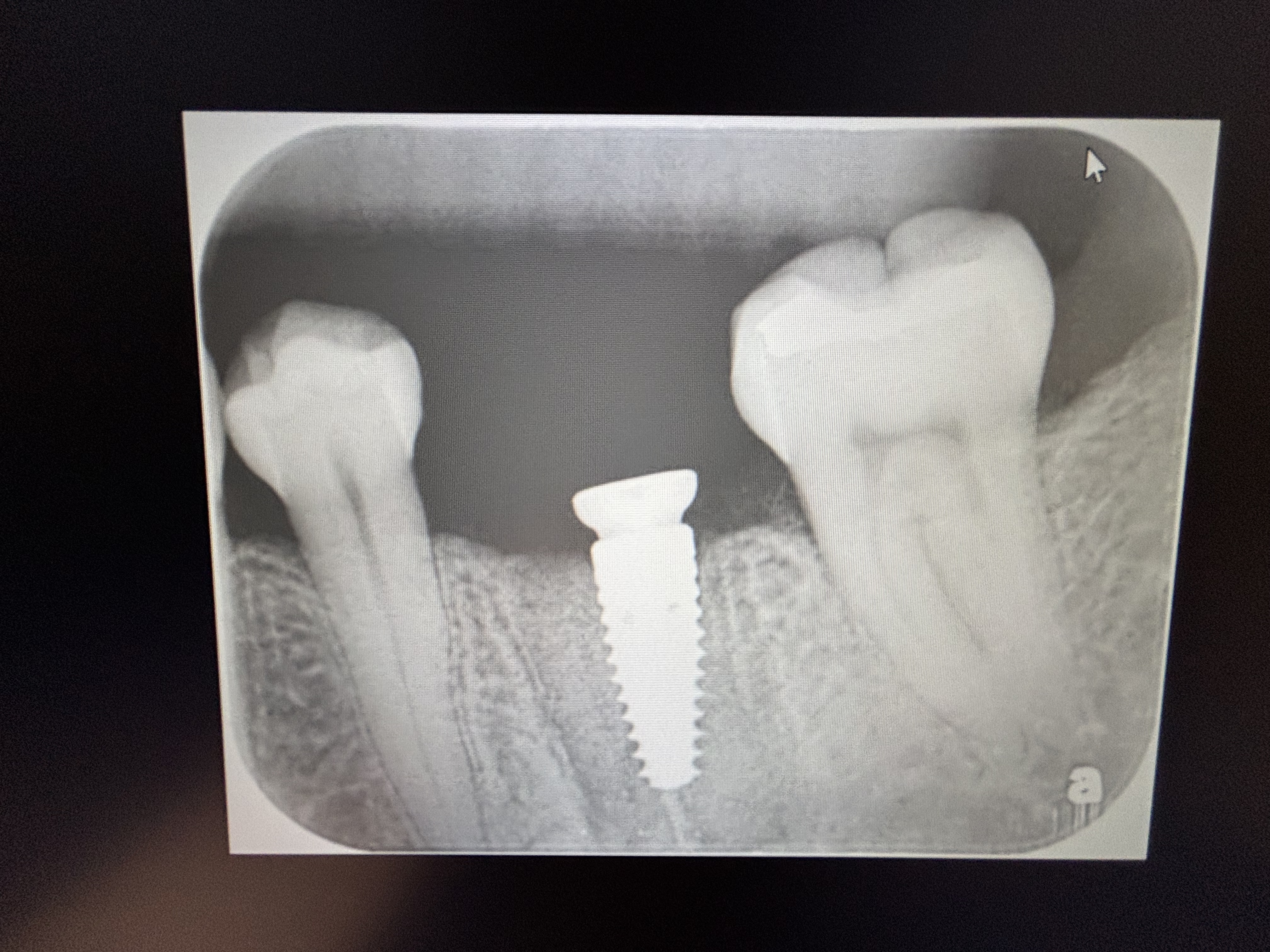

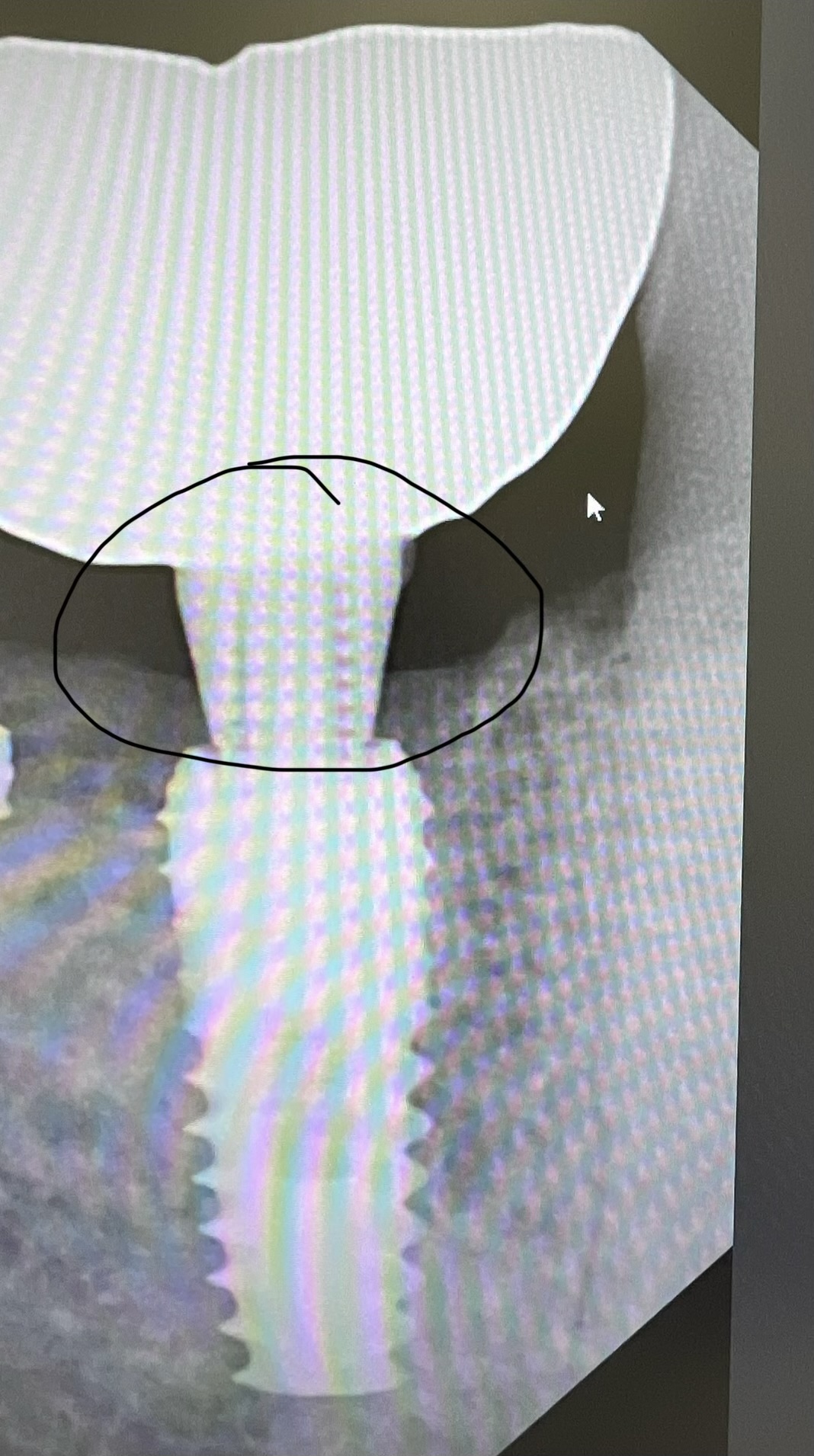

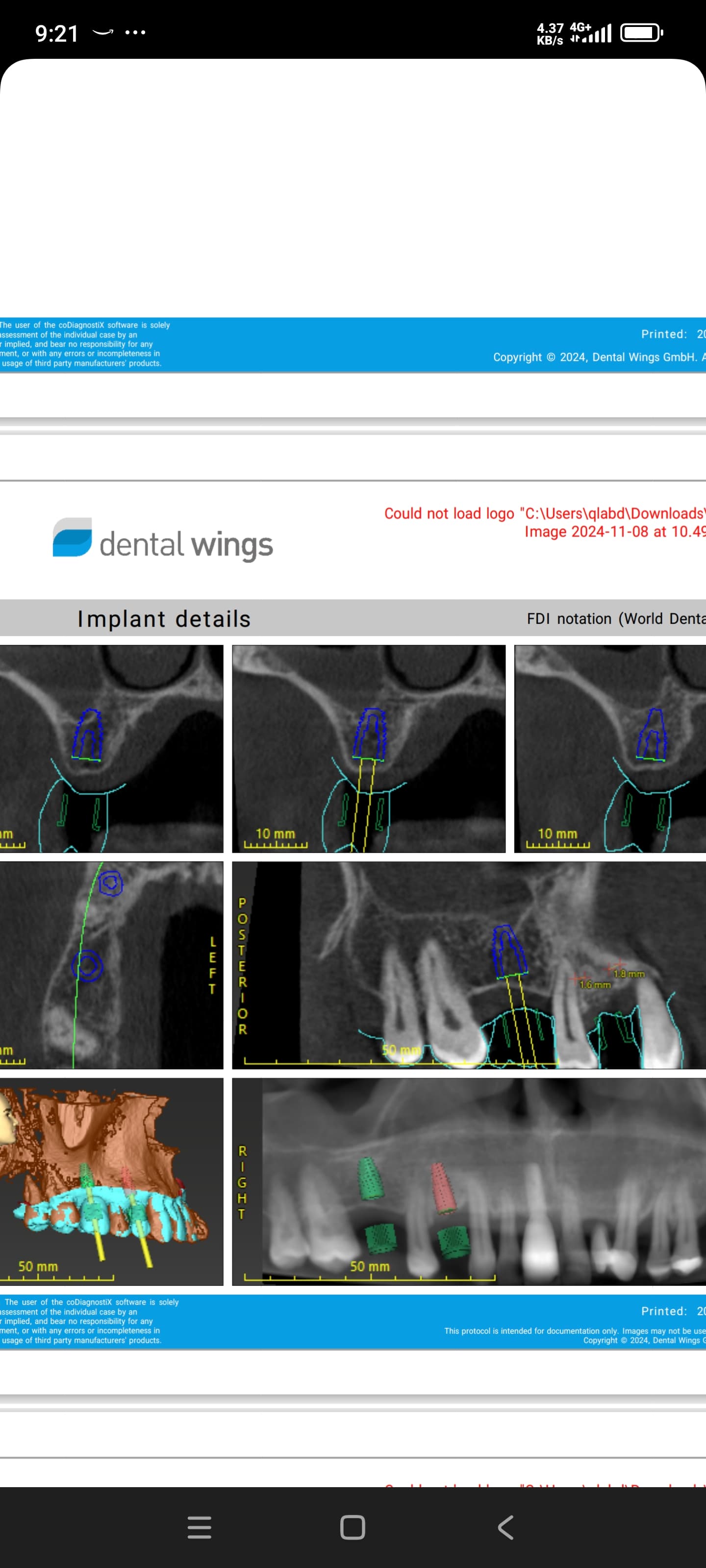

Loose screws were a problem in the old days before torque wrenches. We were taught to hand tighten as much as possible. Not very scientific! Using after market abutments and screws ( i.e. from a different manufacturer than the implant) can be a cause as the parts can exhibit micro-movement. Also, occulsion should be suspected as the number one culprit. Take a film at a perfect perpendicular angle and check for any gaps in the abutment/implant interface as well as the crown/abutment interface if cemented.

Dan

2/19/2019

I agree with Vladi and mpedds . if you will block the screw,

you'll not be able to find the real cause of this screw loosening

and at the end you risk to have a breakage !! somewhere in the

prosthetic work.try to understand what is generating the loosening force .

Ed Dergosits

2/19/2019

The days of screws becoming loose basically ended when systems were developed with platform switched morse tapered internal I/A connections. I have not placed implant without this type of I/A connection in more than 7 years. It amazes me that they are still in use. Implants without such a design are very prone to screw loosening for many reasons. Unfortunately I placed many with this design and they are a headache. I have used Ceka bond on several with mixed results. Be very careful if you use Ceka bond to only coat the abutment screw with a very light coat of the material. If excess material exudes out of the I/A interface the results will be terrible. Best advice I can give is to never use an implant system that does not have a platform switched internal tapered connection. Tissue becoming trapped at the interface of these antiquated systems is likely more the culprit than not using a torque wrench.

7000 implants and countin

2/19/2019

Luckily I don’t see this problem as much as I did in tha days of external hex implants. They squirting Impregum impression material into the screw channel. It sets quite hard and acts as a physical barrier to screw rotation

Dr Dale Gerke, BDS, BScDe

2/22/2019

I would guess that there are a variety of materials that would lock screws into place (many mentioned above). I never use any of them but my predecessor colleague used to use Ledermix cement which certainly worked well in regards to locking the screw.

However I add a word of caution. I have tried removing many screws and abutments that have been locked into place by my predecessor. Many other prosthodontists have also contacted me about removing screws and abutments placed by the same colleague. To be blunt it can be a nightmare. To date I have been able to remove all screws but getting the abutments off is not so easy. You are always “sweating” while applying force because you never know whether you might break the implant. To date I have been able to remove all abutments except one (which luckily for me was on an implant with terminal implantitis so it was not a disaster).

Therefore I would suggest that any locking cement be very carefully applied and restricted only to the screw. However as mentioned by Vladi Dvoyris, screw loosening (or abutment loosening) is usually a symptom of a mechanical problem – which may require something more that locking the screw into place.

I also agree with other comments that if you use a locking material, you need to be minimalistic with it. If it extrudes into the fixture platform surface then a gap with eventuate after time and it will cause inflammation and infection. As well, the comment that internal fittings have reduced the problem is correct. I think it is because the forces placed on the hardware are distributed better (more evenly) and more onto/into the implant body than on the screw (such as with external hex fittings). Thankfully things have improved dramatically over the last 15 years and seem to be getting better all the time.

Rob

2/23/2019

I had a similar issue. I placed four Nobelpharma Mark 2 (external hex) implants into augmented bone in 1993. (Scotland UK) These replaced two premolars and the first two molars in the upper left. The patient is an unashamed bruxist.

He broke porcelain. He bent abutment screws. He loosened the abutment screws every other year. Sometimes he would break the screws. He broke teeth, wore through metal crowns, destroyed night-guards. The broken screws were generally very easy to retrieve except when they were bent. We collected a store of abutment screws for the patient. One broke and its end was wedged solidly in the depths of the implant. It was still possible to place an abutment screw that has 1 mm shaved from its end. At the time, we used Nobel components to fit the external hex. So, the problems with external hex error transfer were present. There were no witness marks or fitting gaps on radiographs to suggest any problems with the fit of the parts.

Move forward more than fifteen years. The patient's medical circumstances have changed. He lost some posterior teeth elsewhere. He has prostate cancer, a blood clotting issue, and does not want to have his otherwise stable implants removed and replaced.

The abutment screw holes have become ovalized. The external hexes are slightly rounded. Optimum torque was not achievable. Two of the implant threads were so abused that the new abutment screws simply turned inside the implants without gaining any retention. We began to discuss possible alternatives such as locators and a removable partial denture.

Like most of us here, I'm a practical guy. I'd moved some radiators recently and, you may know, the water joints are made tight with PTFE tape. So, could the same be done with a loose-fitting abutment screw? I discussed the idea with the patient, explaining that it should be regarded as highly experimental.

It turns out that this works just fine. I wound about three revolutions of dental floss around each screw and regained screw retention. Note that it is also possible to remove and refit the screws too.

The screws have remained solid and properly torqued ever since the bridge was re-assembled. All has been well now for almost five years.