Mill Custom Abutment for Implant in the Office?

Dr. PJ, a periodontist, asks:

Do you know if there is a system that allows you to mill a custom abutment for a dental implant fixture in the office? I know about a number of different system that will allow you to scan and then mill the custom abutment at a remote dental laboratory. I would like to be able to scan the implant fixture and then mill the custom abutment chair side like with a CAD/CAM unit? Has anybody tried this? What system would you recommend? What materials would you recommend for milling?

5 Comments on Mill Custom Abutment for Implant in the Office?

New comments are currently closed for this post.

Carlos Boudet, DDS

4/26/2010

I am not aware of any system that presently allows you to mill a custom abutment in the dental office.

Sirona has announced that they are working on the ability to mill custom cad cam abutments for selected cases/implant platforms with the cerec InLab system, but who knows when it will become available.

It would be nice though, since I have Cerec in my office.

tarun agarwal

4/29/2010

Sirona CEREC system allows for milling of customized Zirconia abutments. This technique is currently being utilized in Europe and is awaiting FDA approval in the US.

Chris Winterholler

4/29/2010

Tarun,

WHen will this be available and for what Implant system are you seeing this work with. I would guess Nobel, Zimmer, 3I. And even though you do it in the office it is not something that you can deliver same day as the Zirc has to be sintered for 3-12 Hours? Correct?

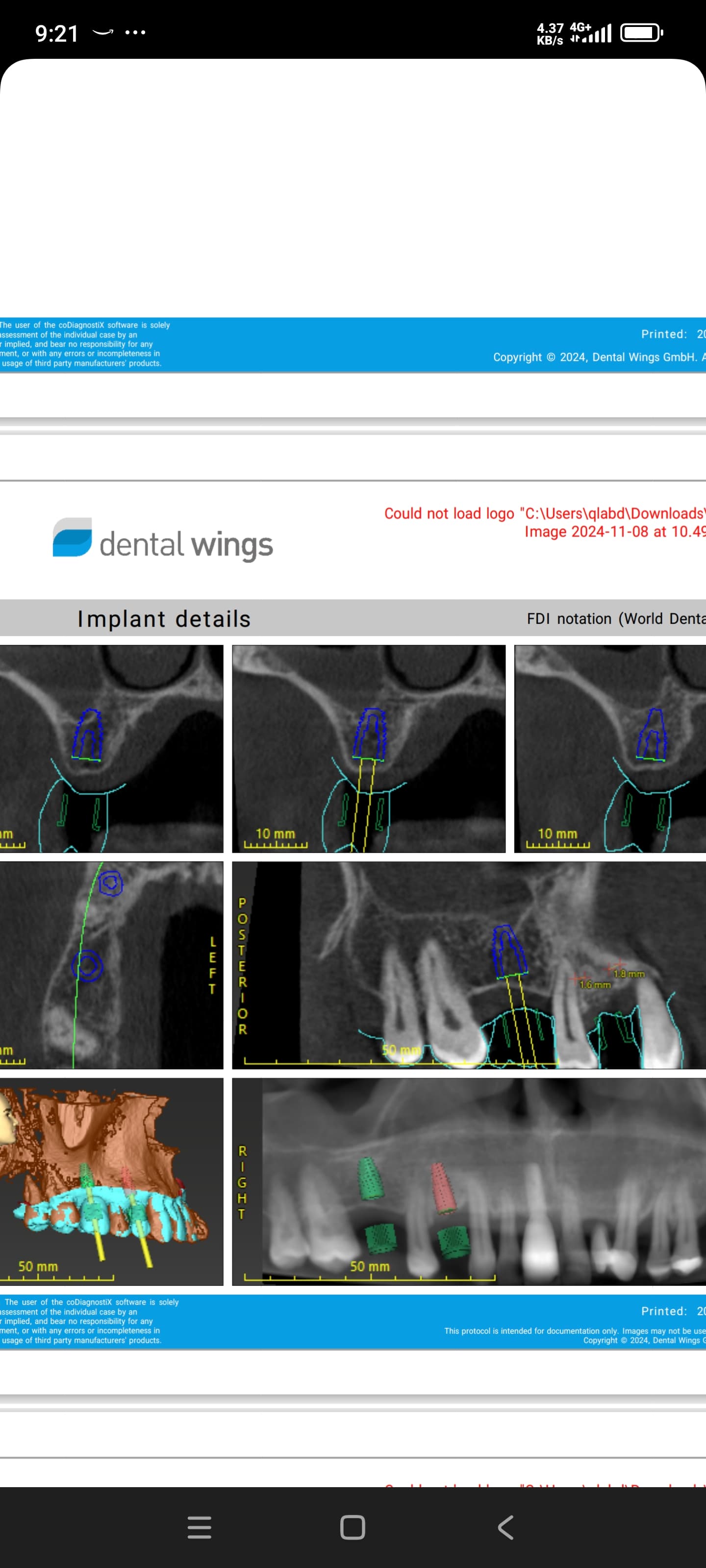

Seems to me that the 3SHape scanner coupled with Atlantis would be the best way to go. THat way they come back in a matter of about 72 hours and you are not limited to Zirconium.

Chris

Jon B

5/31/2010

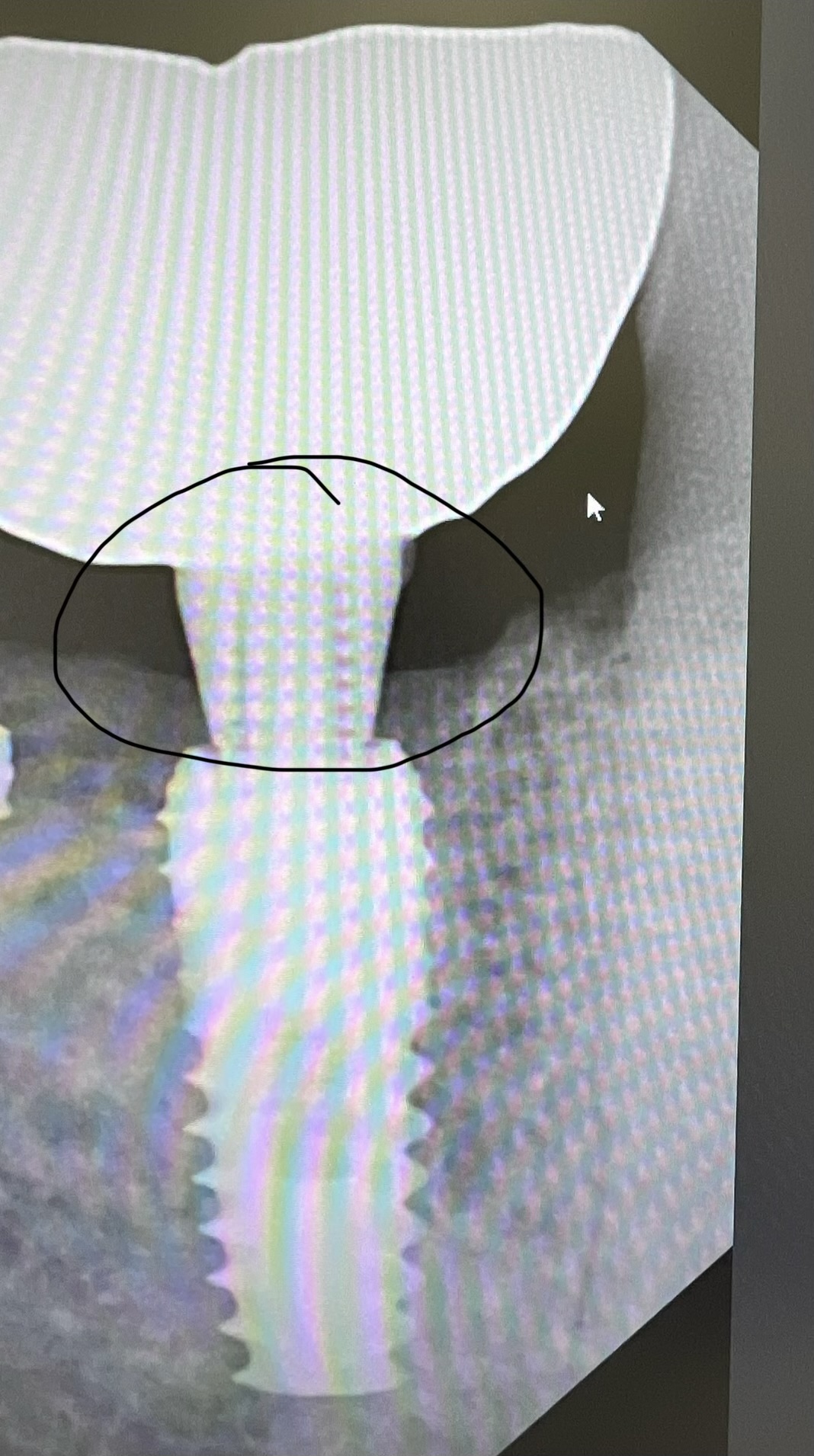

The interface for an implant has a very tight machining tollerance. A desk top mill would generally have difficulty in meeting those machining requirements. I suspect the cost of all the needed software, hardware and technical expertise would require a high volume to be cost effective.

Jon

keith goldstein

7/24/2010

The titanium bases would never be milled by a Cerec machine but would have to be sold to the dentist with the cerec. Green state zirconia would have to be milled out and then sintered. Current sintering ovens are about 10 hours and the microwave technology which is out there has had mixed results and I hear about potential small units but wait till you see the price. Once this is sintered then you have to cement them onto the titanium bases.

Cerec has to license the titanium base design from either the implant manufacturers, buy a third party provider, or create their own and then go through FDA.

Currently the 3shape scanner is the only real viable option these days when it comes to having software to mill out custom abutments be it zirconia or titanium from a very few select milling centers that have the capacity to mill out these types of abutments.

I realize that anything is possible what i wonder is truely how much it will cost the cerec doctor to do this in time and money and equipment given that in the USA there is an overcapacity of titanium and zirconia abutment milling centers which inevitably means lower prices.