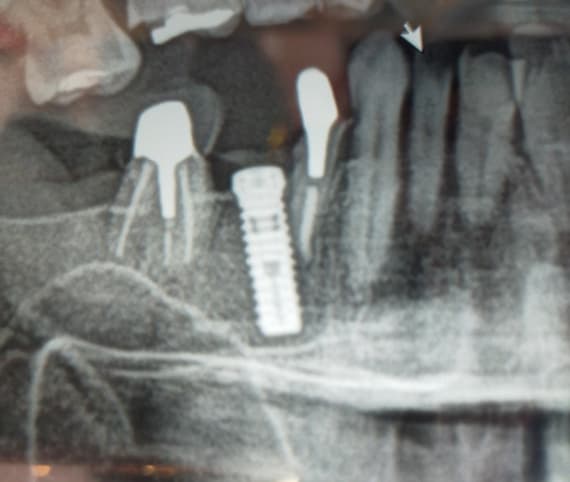

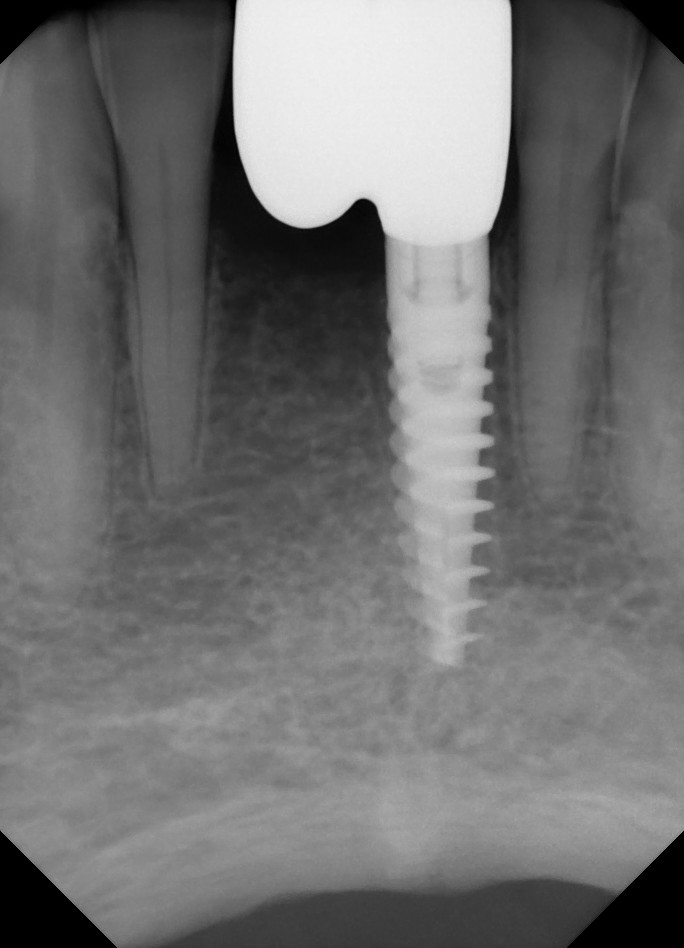

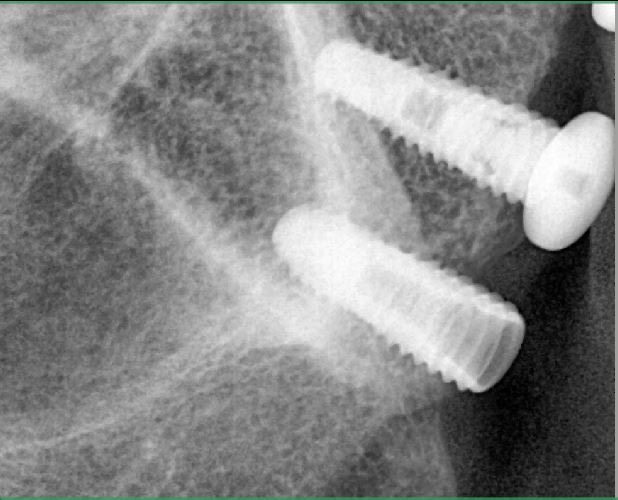

Bacterial Colonization Around the Micro-Gap?

Dr. H. asks:

Recently I have been hearing a great deal about the problem of bacteria

colonizing around the micro-gap between the dental implant fixture and the

abutment. I have heard that this micro-gap and bacterial colonization

can produce bone loss.

Is this a real problem to be concerned with? If so, what are the best ways to prevent this? Is it simply an an issue related to a specific dental implant design? Thanks.