Dental Implant Fixture Got Stuck: Any Ideas on Why This Would Happen?

Dr. J. asks:

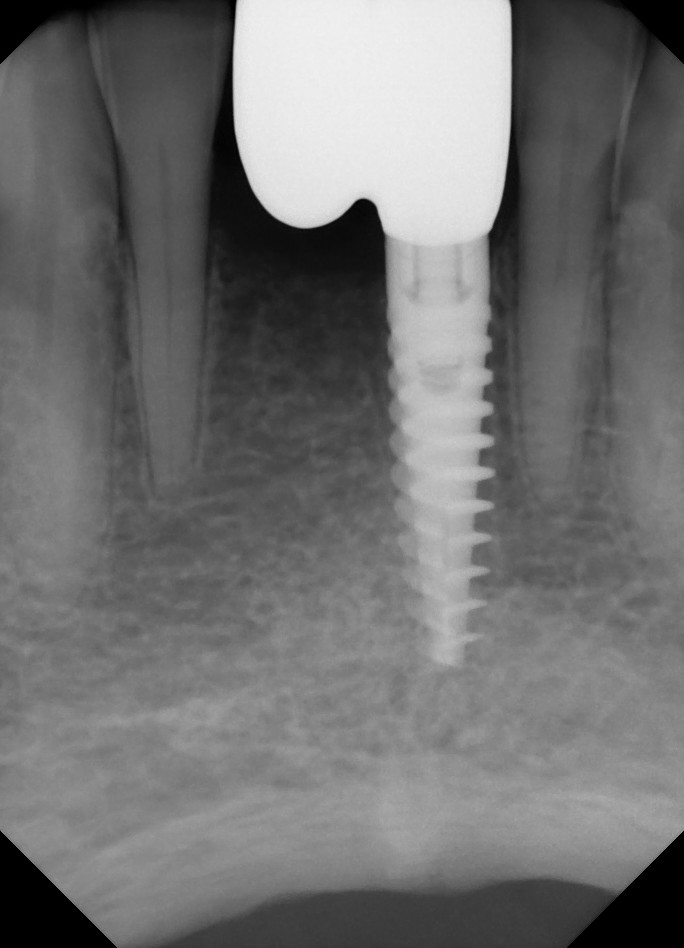

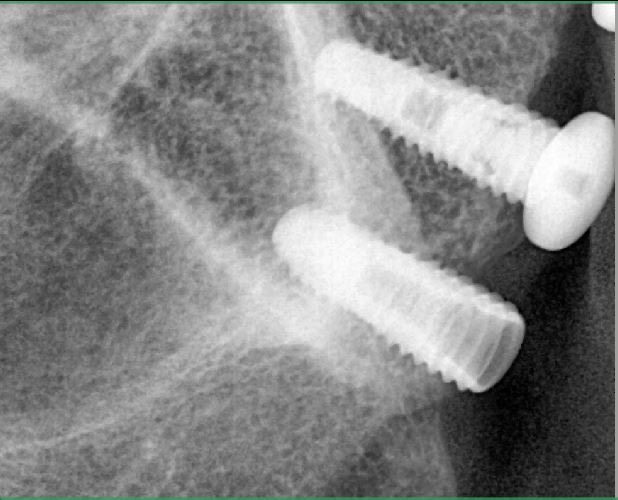

I recently placed an Astra 4.0×13 implant in the #5 area [maxillary right first premolar; 14]. The implant fixture became stuck at the midpoint of the depth of the osteotomy during installation. I removed the implant and re-drilled for the same diameter implant. But when I re-attempted to install the implant it again became stuck at the midpoint of the osteotomy and the motor was still unable to drive the implant to place. . Finally I placed 4.5x13mm without any problem . Any idea why an implant should become stuck in an osteotomy channel? Any recommendations on how to prevent this?

18 Comments on Dental Implant Fixture Got Stuck: Any Ideas on Why This Would Happen?

New comments are currently closed for this post.

Dr.B

7/18/2011

Probably bone density issue. Two options, reverse torque then retorque in. Or tap bone prior to placement.

roberto sosa dds

7/19/2011

next time try placing implant by hand with wrench ..back up plan ...

Dr. Gerald Rudick

7/19/2011

You prepared an osteotomy for a 4.0 x 13 Astra implant, got stuck, removed it.... and tried again...still stuck!!

Then you simply placed a 4.5 x 13 mm implant ( brand not mentioned), and it went in easily...makes no sense.

Is it possible that the Astra implant had an improper label and was larger than what you thought...because 4.5 is definitely wider than 4.0.

Are you sure you measured the size of your drills correctly?

In the Maxilla, Osteotomes can help you with situations like this, as the bone is less dense and can be manipulated by torquing the instrument to widen the hole....or use bone taps as suggested above.

Good luck.

Gerald Rudick, Montreal

DR LDS

7/19/2011

It must have been very dense bone. I use Astra and this has never really been a problem. I would not let this event cause you to overprepare in the future. Sometimes the hand wrench is better. It gives more torque than the machine. If you were trying to put a 4.0 on the top then you should drill to 3.35 for ASTRA 3.7 if it is mandible dense bone.

Dr. danesh

7/19/2011

Dear colleague,

I have seen such a case in D1 bone.

But in the maxilla, it is somehow amazing.

If I where you, I would do the ff.

check the drill.

check the size of the fixture ,as one said ,it might be mislabeled.

and finally to use the torque wrench manually to try to insert the fixture , at the end of insertion , it is advisable to unscrew the implant and then use the machine to insert it with 35 NCm.

I hope it helps and good luck.

Osurg

7/19/2011

Using a tap is a good idea. Insertion with a torque wrench also works. Be careful not to tighten against excessive resistance. You can end up with a psudo cold welding of the carrier and not be able to separate it from the implant.

Vipul G Shukla DDS

7/19/2011

It does not make sense that a wider diameter implant went in where a 4.0mm was not proceeding beyond the half-way mark. My possible troubleshooting options:

1) Osteotomy was for a tapered implant, and a straight cylindrical fixture was attempted to be placed, so final implant shape and osteotomy do not match.

2) Incorrect settings were chosen on the implant motor re: torque and RPM.

3) Your drills are old/worn out and hence the osteotomy is narrower(although should not be an issue in the maxilla)

4) Implant was mislabeled by manufacturer.

5) The motor's torque calibration is off and needs re-calibration.

Just my 2 cents of input, I could be completely wrong on all counts.

In the end, it's an extra unreasonable expense to you and I hope you had it returned for a refund from Astra.

Dr J.

7/19/2011

It could also have been due to the fact that the inside of your implant was stripped from the initial pressure. Astra is a pure titanium and fairly soft so it strips and breaks easily. I think the company has realized that and is going to Ti alloys which are a lot stronger. This is the only system that I have used that

the implant body has broken on me.

Robert Davidoff

7/19/2011

First question is are you using the Astra Burs or burs fromn another manufacturer? Makes a difference, especially in dense bone. Is this a tapered implant? When you were drilling, did you have the sense that the bone was dense?

Dr Lee Nightingale

7/19/2011

This does sound funny, I can't remember a time when I have had to tap maxillary bone in the premolar region. My Money is on one of those crazy situations when you pick the wrong size and the wrong instrument and you just don't see what's happening. If you successfully installed a 4.5 but couldn't get a 4.0 in then something more fundamental has gone wrong than that of a simple surgical problem.

The good news is the procedure was completed with a happy ending.

Cory Fratus, CDT

7/19/2011

You were more than likely in dense bone and did not tap the site, or, only tapped it coronally. Try taping all the way to the axial point of the osteotomy. Also- if the implant inst completely parallel (even if it looks parallel to the naked eye, it will have some sort of taper to it). This said, you may have to also use a profile drill in this site. The profile drill will coronally shape the osteotomy according to the implant body and shape. I hope this helps. I know how important it is to have primary initial stability, expecially in cases where you want to temporize or immediately load but the first step is to get the implant in the bone :) So, tap, profile and all should go smoothly- especially when dealing with type 1 or 2 class bone.

Juan collado dds

7/19/2011

I think when he try place the implant if full length of the osteotomy is complete the only reason for implant stuck the handpiece has wrong inclination and angulation and put implant in wrong side.Juan collado dds 7-19-11

AMIT PATEL DDS

7/20/2011

MY 2 CENTS:

ASK YOURSELF SOME QUESTIONS-

1. PATH OF INSERTION OF FIXUTE 4MM DIAMETER MUST NOT MATCH THAT OF OSTEOTOMY!

2. OSTEOTOMY WAS TOO LARGE FROM THE BEGINNING-MAY BE APPROPRIATE FOR 4.5 MM DIAMETER AND WHEN YOU PLACE 4 MM FIXUTE IT HAS MORE THAN ONE DIRECTION TO BE INSERTED AND HALF WAY IT GOT STUCK.

3. ONE COMMON QUESTION HOW CAN SCREW GET STUCK ON A WALL WHEN EVERYTHING WAS RIGHT-IT WAS JUST A BAD DAY FOR THE OPERATOR. OPERATOR PLAYS A BIG ROLE HERE. WE ARE HUMAN AND NOT MACHINE AND SITUATIONS LIKE SCHEDULE, DIFFICULT PATIENT, OPERATOR'S EXPERIENCE PLAYS A BIG ROLE IN THE OUTCOME OF SURGERY.

THANKS

4.

Richard Simons

7/20/2011

(Just a point of clarification; the body of the 4.5mm Astra fixture is 3.5mm diameter, flaring to 4.5mm at the coronal aspect)

samantha pugh

7/20/2011

OK LETS CLEAR UP SOME CONFUSION HERE!!!!

The Astra 4.5 is a 3.5mm implant body with a flared cone head that is 4.5mm wide. so in fact the majority of the implant is 3.5mm wide hence why it smoothly inserted into your osteotomy.

Astra have recently introduced the TX implant which is tapered only at the apex. This allows underdrilling of a site in d4 bone only and the small tapered section is just to facilitate entry of the implant into a smaller osteotomy site.

Unfortunately, Astra are slightly mis marketing the product and tend to imply that the osteotomy can be prepared one drill size smaller. This is only really acceptable in real D4 bone bordering on candyfloss!!! Everywhere else you should prepare a normal osteotomy site of 3.7mm for a 4.0mm implant or 3.85mm in dense bone type.

I have definately experienced this problem and have used Astra very successfully for 5 years. I think there is a tendency to assume maxilla bone is 'soft' and as the 4.0mm implant requires so few drills to prepare the osteotomy you dont get a good feel for the bone. I have since learnt to really feel the bone when im driling and not just assume i can underdrill a bit to get better primary stability.

The drill kit also has a lot of drills that look similar in size so always check the shank for the size before using. I rely on my nurse to replace the drills once clean and have found a few misplaced which i could have accidentally used if i didnt check them.

In future you did the right thing by removing and redrilling the site, but do as others suggest and use the hand wrench to finish home the implant with slow turns so as not to generate too much heat.

samantha pugh

Denise Jansson

7/20/2011

Thanks for your comments.But I must have expressed myself badly.I drilled of course after the drilling schedule for both the 4.0 and 4.5. When I discovered that 4.0 does not work, I increased the diameter and placed 4.5 instead.I noticed all the time that the bone was very soft and felt almost no resistance when I drilled for 4.0.

Baker vinci

7/20/2011

This question lacks "beef". The situation is a shop 101 scenario, which typically is something all of us run in to. The fact that this company misrepresents diam. Size, is one reason I only place three brands of implants. I might suggest, when you are placing all implants, stop when you begin to feel the first bit of resistance and seat the implant by hand. This will increase the longevity of your handpiece and allow you to predictably assess the torque. That tight seated feeling ,just greater than 35ncm, sure is satisfying. Someone drop a question that generates some heat! Bv

Dr. Dan

7/22/2011

Everyone's suggestions here are good. Sometimes the implant will not go all the way in. Reasons for this are dense bone, something else that is dense is in the way, or simply the osteotomy needs to be irrigated more to remove any residual bone.

The following can be done when this situation arises: Tap the bone, use a torque wrench, but make sure you know what the manufacturer's recommendation is in regards to the maximum torque, or insert, back out and re insert again.

Also, when a situation like this takes place, make sure you are going at the same angle as the osteotomy. Make sure your osteotomy isn't all curvy either.