Cold weld platform to abutment to decrease bacteria collection around implant?

There are implant systems that have a Morse taper and form a cold weld when the abutment is torqued down into them. This cold weld is supposed to exclude bacteria from penetrating between the two components. In this regard this system is supposed to be superior to those systems which do not form a cold weld between abutment and implant when torqued together. Is there really any advantage to the cold weld? If so is there any way to convert systems which do not have the Morse taper so they could form a cold weld with the abutment?

10 Comments on Cold weld platform to abutment to decrease bacteria collection around implant?

New comments are currently closed for this post.

John L Manuel, DDS

8/12/2014

As with crown preparations, the more parallel the mating surfaces, the easier to get a good seal. There are a wide range of tapers in implant abutment design, and some controversy about whether a total, electron microscopy proven, seal is needed.

The experience many of us using the Bicon Morse taper connection is a dramatic reduction in tissue irritation, peri- implantitis, compared to screw retained designs with no, or little taper. In fact, an almost total lack of problems at the implant/abutment connection.

Additionally, bone tends to grow over, across, the junction over the years. Bicon has some microscopic cross sections of the seal, as well as some research documenting the bone growth over the connection on their site.

There are reliable manufacturers who have a less parallel taper with screw retention around also.

There are pros and cons to Bicon's reliance on the taper fit, cold welded, connection alone which the operator needs to address in the design of each application: one cannot set up a high angled abutment so as to become rotated on loading or the connection may release the crown/abutment pair. With parallel placement, parallel, broad contacts this has not been a problem for me. Also, Bicon has introduced a "super parallel" 2.5 mm abutment taper to reduce the problem on anterior teeth.

So, one cannot just throw in bodies and abutments without loading considerations, but this planning is required of all implants.

Dr. Sudin Shakya

4/4/2022

I am having problrm of implant crown dislodging in anteriors in bicon implants. Can u please help.

My email is sudinshakya25@gmail.com

I am from Nepal

John L Manuel, DDS

8/12/2014

Regarding your question about modifying a non-tapered implant abutment system to a "cold welded" Morse taper type:

1 - The precision required to machine these close tolerances in the mouth, or out of the factory precludes such internal modifications.

2 - If you have an existing, placed, integrated, non-tapered implant suffering from abutment/implant leakage and tissue degradation to the point of bone loss well below the junction, sometimes the best way to circumvent the leaking junction is to do a normal but very parallel crown preparation and cement a new crown to cover the defective seal area.

Dr Bob

8/12/2014

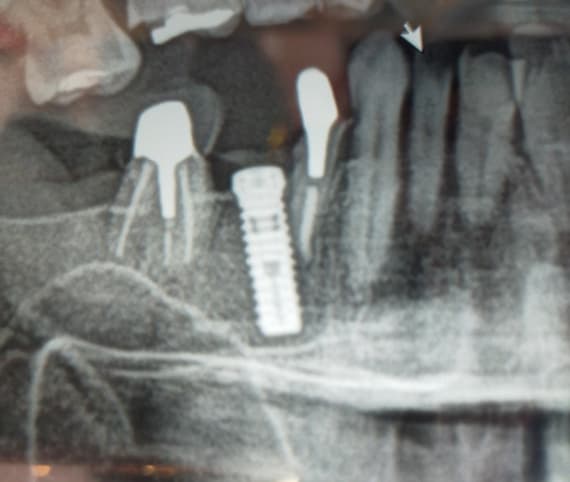

Most all implants work well when properly placed and restored. There is such a thing as micro leakage, and it is not good for implants. Platform switching and attention to implant placement as to the depth of the gingival sulcus must be planned for before surgery. If at second stage the implant platform is six to eight mm below the gingival crest then micro leakage at the junction of the abutment to the implant platform will be of greater concern than if this junction is at a depth if one to three mm below the gingival crest. Planning your cases with an understanding of the advantages and limitations of different implant systems is important. Each manufacturer will tell us that the implant they have is the best and they will have proof of why this is so. Dr. Manuel is right to warn us about the tapered "cold weld" implants spinning loose. They are good implants but have limitations.

Tuss

8/13/2014

Many systems that say they have "cold weld" still have a gap between the abutments andimplant interface, just becuase two components wedge down tightly it does not mean that a physical gap is not present. They used to go on about "hermetic seals" etc. and again shown to be untrue

CRS

8/13/2014

I agree with Dr Bob, there are no absolutes in implant dentistry and sales reps will tell you want you want to hear. I would not advise modifying any implant system you will be standing alone if there is a problem. There is no holy grail of the perfect implant, patients have dirty mouths and good follow up and maintenance of the restorations with good treatment planning at the get go are key. I can't believe some of the stuff a sales rep will say, however a good one who understands his system well can be a very valuable asset to the implant team. I feel your pain, I don't restore being a OMS but I value the principles of restorative driven surgery. Several things need to go wrong usually for an implant to fail micro leakage is only one. Hope this helps.

John Manuel, DDS

8/13/2014

Agreeing with these other posts, consider that microleakage is a small problem relating to all the other factors which could bring about bone and soft tissue problems/

As mentioned, microleakage is of greater concern with implants designed to be submerged deeper into the tissues, and less of concern as the abutment/implant junction lies closer to the surface.

Over and under contouring, overlying proximal contacts, etc. pose more common serious potential negative sequalae.

Some implant installations may require a solid mechanical anti-rotational lock, and others may not.

Each operator should be knowledgeable in several reliable implant systems and continually learning across the field.

As mentioned, MOST implants are successful. We are all interested in and charged with the continual improvement of the art.

Don Rothenberg

8/19/2014

I have been a long time user of the Bicon system...it is the only true "cold weld" system that I am awear of.

We have virtually no peri-implantitis problems. We are very careful when cementing prothetics...sometimes even using rubber dam.

I have never heard of a way to retro fit other implant systems with the "Morse tapper...cold weld".

But I am very happy with Bicon...in fact it is the only implant we have ever used, since 1986...we do about 100 implants a year.

Thanks for all your input.

ezgator

8/19/2014

Funny, everyone is so worried re. leakage at the abutment implant connection yet no one has mention that a tissue level straumann has its connection well above the bone and as such does that not eliminate the problem of leakage and bacterial contamination? Am I missing something??

Robert J. Miller

8/23/2014

Let's get real....ALL abutment connections have a degree of microleakage. But the problem with using the term "leakage" is that there is a difference between the presence of an architecture that may harbor bacterial pathogens and one where there is active percolation of those microorganisms. The movement of bacteria within an implant/abutment connection requires a "plunging effect" that moves fluids in and out of the interface. Of all of the connections we have had available over the last 50 years, demonstrably the worst in class have been the flat-to-flat connections. Those include external hex and tri-lobe connections where you can demonstrate lifting of the abutment off of the implant top in shear loading (refer to the Zipprich study from Germany). The least amount of lifting, and biomechanically the lowest plunging effect, are the cone-fit, morse taper, and ferrule attachments. Now, we can demonstrate that the greatest bacterial reservoir is actually in the cone-fit group because of the scoring of the interface as the surfaces mate. However, because this architecture has a low plunging moment, and because the interface is well below the tissue level, we see the greatest retention of bone post-loading. So we should be talking about fluid dynamics, biomechanical stability, position of the implant/abutment interface, and cyclical loading to failure of the retention screw rather than the presence of microorganisms alone. To date, multiple studies have shown that the most stable abutment connection has actually been the ferrule attachment, where there is an inside cone-fit together with and outside sloped shoulder to seal the connection.

RJM