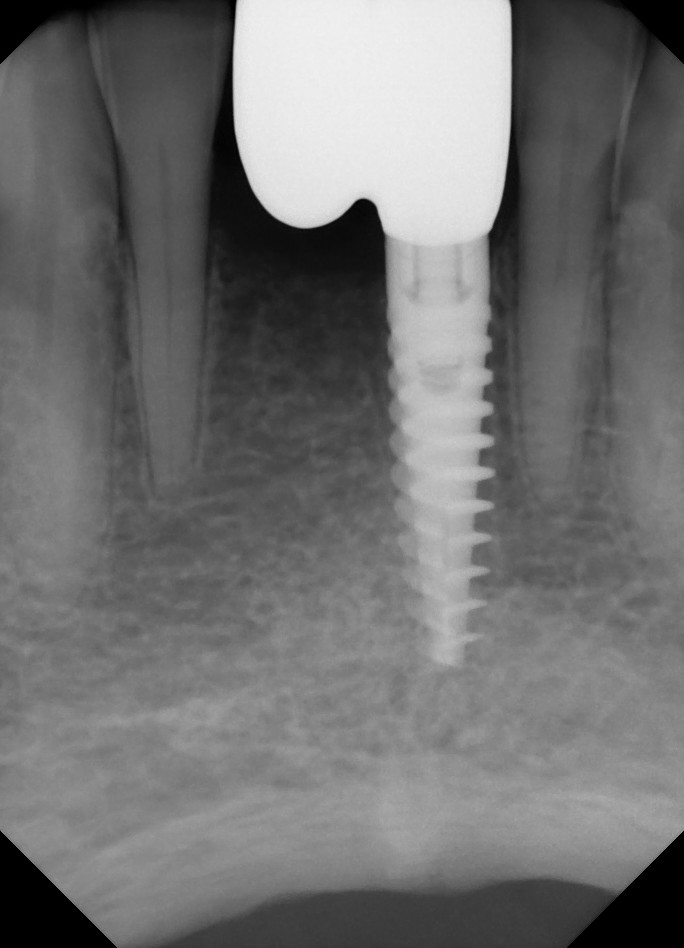

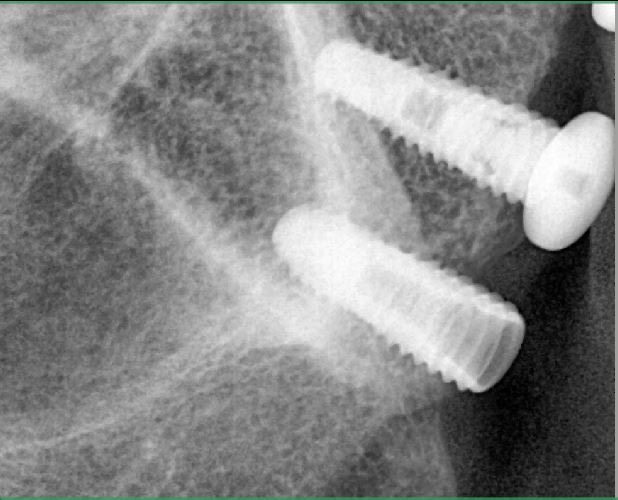

Custom 3D-Printed Resorbable Bone Grafts for Ridge Augmentation

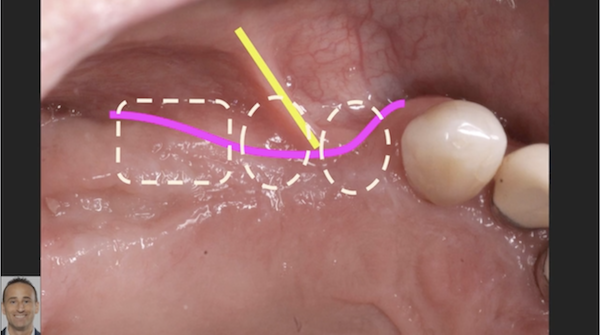

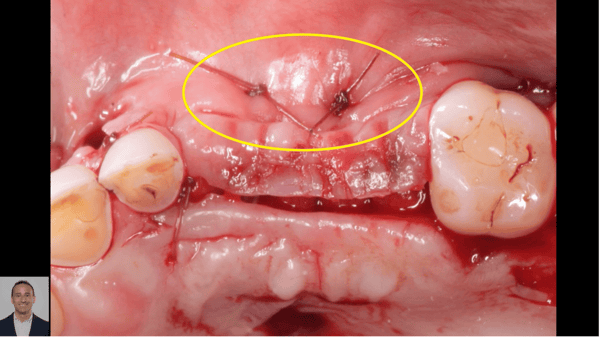

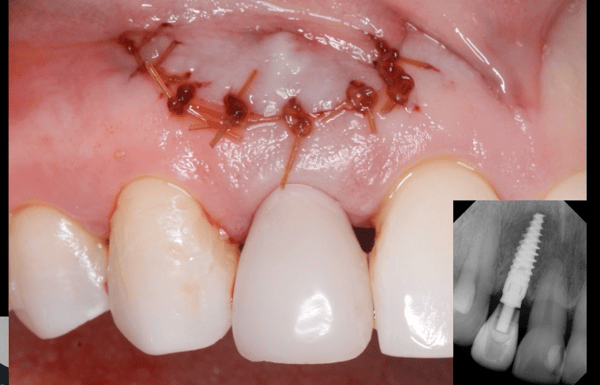

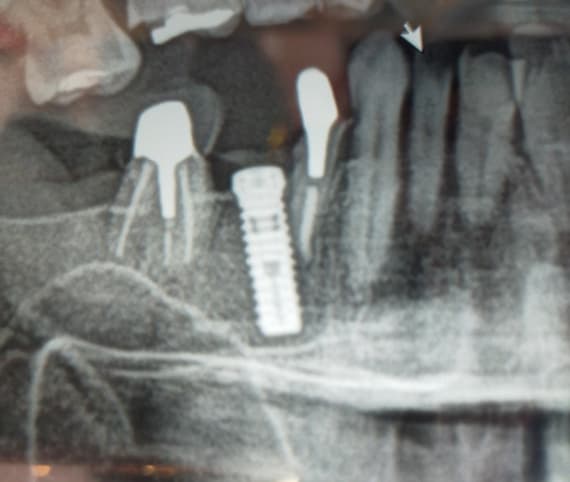

The one area of oral bone regeneration that remains unpredictable is ridge augmentation. The following images are designed on a CT scan. The image is then printed by a 3D printer, producing a resorbable beta tricalcium phosphate ceramic bone graft that fits your patient precisely. Please feel free to leave any comments/questions below. Thanks. Greg Steiner Steiner Biotechnology

28 Comments on Custom 3D-Printed Resorbable Bone Grafts for Ridge Augmentation

New comments are currently closed for this post.

Fernando M Munguia

5/25/2017

Sound very interesting. I would like to have information about it. Any clinical trials or RCT's studies. please keep me informed.

greg steiner

5/25/2017

Thanks for your interest. There are no formal clinical trials just 6 years of R and D. If you want to follow the progress you can call our office and request to be put on our email list.

Arshaad sibda

5/26/2017

I've been doing it for a few years.

My papers will be submitted for review soon.

You welcome to contact me.

Regards

Scott D Ganz DMD

5/26/2017

Send me an email, and we can discuss how long this process has been around... drganz@drganz.com as you did not leave any contact information.

greg steiner

5/26/2017

Arshaad

I do not have your contact information but please feel free to contact me through my company email or phone number. Greg Steiner Steiner Biotechnology

greg steiner

5/26/2017

Hello Scott

I would enjoy hearing your perspective on this technology. You can contact me through our company email or phone number. Greg Steiner Steiner Biotechnology

phil

5/25/2017

Exciting times...Computer simulations are helpful to understand the principles, but what would be really great is if we could see some more real life photo's of the actual graft in a patients' mouths (before, after etc.) Do you have more real life cases using this technique?

greg steiner

5/25/2017

Phil

We are in the process of documenting additional cases and will be sharing them with those on our email list. You can call the office to get on the list and we will update you with cases as they are documented. I don't it appropriate that I use this site for that purpose.

Anthon DDS

5/25/2017

Hello Greg,

I've seen you wrote "There are no formal clinical trials just 6 years of R and D". Did you put together some stats during this period ?

greg steiner

5/25/2017

No just monitoring results.

greg steiner

5/25/2017

No, just observing which surgical protocol produced the most favorable results.

Peter Fairbairn

5/25/2017

Great stuff Greg as always a thinker . I have been working on this as well in the UK but have had numerous small issues ..... but happy o see good thought precess

greg steiner

5/25/2017

Peter

Good to hear from you. You know how hard it is to do. I honestly think it is the hardest thing I have ever done.

Pradeep

5/25/2017

i have done one case on 3d printing bone graft in ridge defect area. waiting for 6months

Sam

5/26/2017

This is not new. Maxgraft Bonebuilder started this several years ago with human allograft.

Ruggero rodriguez y Baena

5/26/2017

Sounds good! I'm working with autologous mesenchymal stem cells from patients gingiva, tooth pulp, periosteum and I'm looking for an ideal scaffold. How can I have more information about yours? Thank you

greg steiner

5/26/2017

Hello Ruggero

The 3D printed structure is a carrier for our matrix. We fill the 3D printed structure with our graft material (matrix) which is osteoinductive and stimulates osteogenesis. Osteogenic cells migrate into (or are placed into ) the graft materiel that is inside the 3D printed structure and are stimulated to form bone in the matrix. When bone is formed in our matirx (graft material) osteoclastogenesis begins and the 3D structure is resorbed. Your use of autologous cells tells me you have thought this through and you realize this is regenerative medicine and no place for cadaver tissue or allografts. Please give me a call at the office and I will hook you up with our chief scientific officer who is a Harvard trained cell biologist. Greg Steiner Steiner Biotechnology

Scott D Ganz DMD

5/26/2017

Great use of technology. However, not new at all... you might want to review some of prior art IP... from 15 or so years ago... send me an email and we can discuss... drganz.com

Geoffrey Bauman

5/27/2017

Another approach might be to print a model of the bone defect so that one may prepare the graft in a sterile environment at the office, and repackage it (of course would want to re-sterilized it if possible). I'm thinking an allograft block such as the "J block" or other. Rather than have to spend time in the mouth shaping it, do it ahead of time and then just place it intrasugically. THREE PROBLEMS:

1) cost of the printed model of the defect (any one have an approximate cost of that?)

2) Can the model be printed and sterilized

3) Graft re-sterilization. Is a there a heat below which an allograft block could be sterilized over a given time and not damage the block structure?

I would even be willing to set aside a time, same day, prior to surgery to adapt the block to a sterile model in a sterile environment for later use that day if it can't be re-sterilized. I just hate to shape them intra surgically with the mess and the time back and forth between the mouth and trimming field. Can anyone answer the above questions? Has anyone tried this?

Thanks,

Geoff

Sam

5/27/2017

Dear Geoff,

Search Maxgraft Bonebuilder.

Regards,

Sam

Oiver Scheiter

6/4/2017

Dear Geoff,

we used exactly what you described 10 years ago.

Italian company (3dblock.com) produced autoclavable defect model. Tutogen J-Block (now Zimmer) was shaped under sterile conditions and then placed in the patients mouth. We even prepared the screw holes. So the actual intervention in the patients mouth took about 25 minutes of mostly soft tissue management.

Worked perfectly. I left the technique because of the allograft.

Best man for this with more than 10 years of experience is Michele Jacotti from Brescia/Italy (jacotti.it)

Sunny regards from Mallorca

Oliver

GB OS

5/28/2017

Thanks Dr. Steiner

Good concept but from a surgical point we are entering unchartered territories both from sterilisation process and cost involved .

Can you please SOE ify what osteiibductive material is used here ?

Am I right in thinking it is corticocancellous allograft ?

Many thanks

greg steiner

5/28/2017

GB OS

Thank you for your comments. There were many uncharted territories in developing this product but they have been successfully navigated. We are a regenerative medicine company and when it comes to bone osteoinduction and stimulating osteogenesis it a requirement. Regenerative medicine uses either bioactive molecules or implanted cells to regrow the tissue that was lost. The resorbable structure that you see is filled with our synthetic graft material that is osteoinductive and osteogenic. In addition our cell biologist is testing the addition of stem cells to further the process and that could be ready soon but I am always overly optimistic. Cadaver tissues are not used in regenerative medicine for a host of reasons. Greg Steiner Steiner Biotechnology

GB OS

5/28/2017

Sorry auto correction

Specify what osteoinductive material

Peter Fairbairn

5/28/2017

Hi GBOS , CaP materials especially BTcP are show to have osteo-inductive potential. There are over 200 published papers in medical research . Now even a number of new papers have been published in the lower impact factor Dental journals .

As a manufacturer of synthetic graft materials , what is the issue with printing and cad/cam manufacture is more regulatory and sterilization problems .

Regards

Geoff

6/5/2017

Oliver,

Thanks so much for the feedback. Could you explain why you stopped the technique a little more. Did you not like using block allograft or another allograft method that you liked better. If you didn't like the allograft block was that because of resorption or exposure or what? How much did the bone model cost from 3dblock?

Many thanks,

Geoff

Oliver Scheiter

6/5/2017

Geoff,

the price was €250,- at the time. I stopped using it mainly because my patients wouldn't accept the allograft. Same with xenografts. For a short period I used the 3d model to adapt autogenous blocks which was also effective but a bit messy and also a little beside the point.

This faded out when we developed a serious of techniques to get around block augmentations.

Firstly we use an advanced protocol for autologous plasma preparation (hopefully it will reach the marke soon) and the Tissue Master Concept to prevent crestal defects.

When we do encounter crestal defects we can solve most of them with Angle Modulation Techniques.

I don't know if that is of any help to you. Possibly those techniques have not reached the states yet?

If it's helpful you might have a look at my linkedin site where I have published some cases.

Sunny regards

Oliver

CV

6/6/2017

I heard that a similar product called Allograft Custom Block (by Straumann) is recently available in the US. Has anyone used this?