Custom-made implant designs: the future?

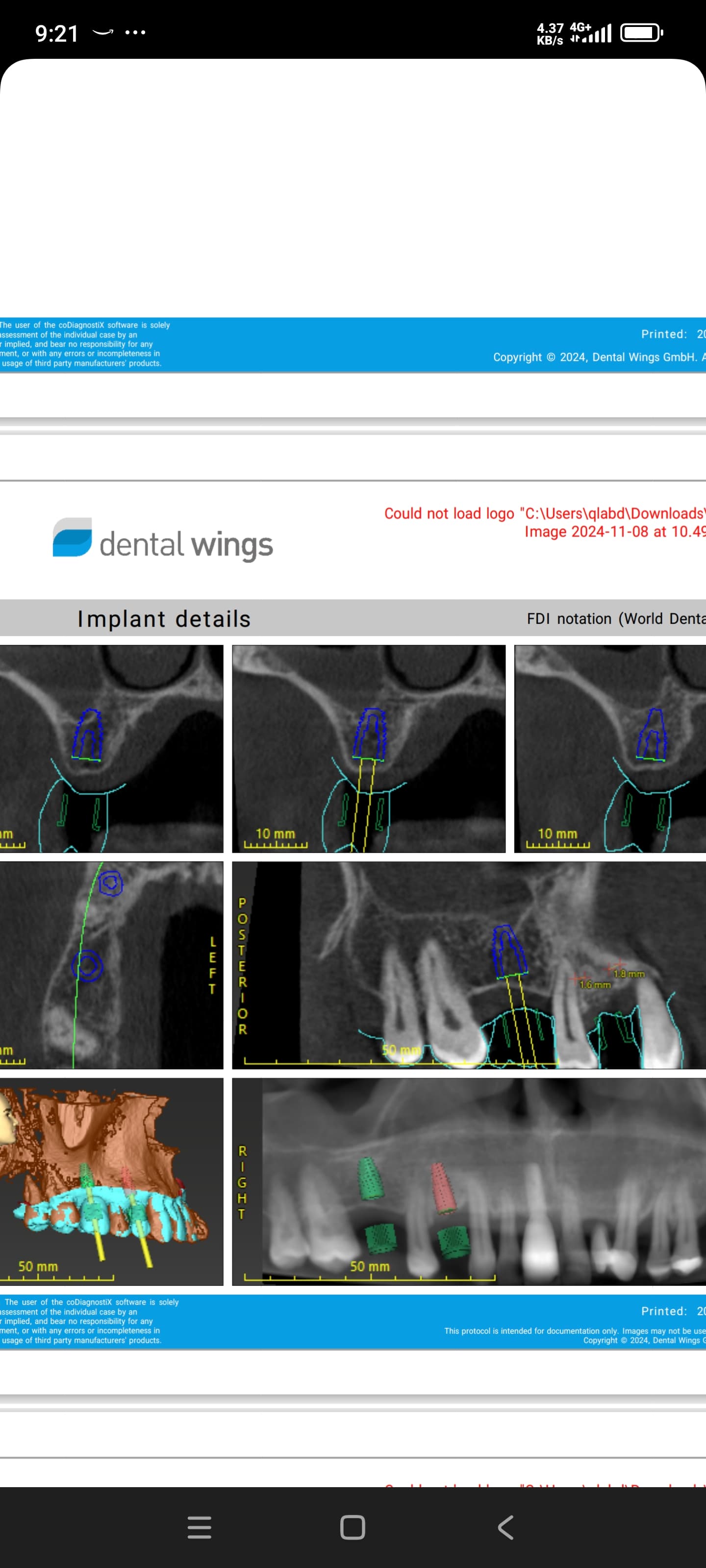

Due to rapid advances in computer aided design/computer aided manufacturing technology, custom dental implants, or patient-specific implant dentistry, is continuing to gain traction with researchers. Of course, the issue is, how do these custom implants perform vs their generic counterparts. A recent study1, investigated the influence of the custom-made implant designs on the biomechanical performance for both an immediate and a delayed loading protocol in the maxillary esthetic zone. The study showed that:

In a comparison of the three implant designs for both loading protocols, a favorable biomechanical performance was observed for the use of root-analogue threaded implant which approximated the geometry of natural anterior tooth and maintained the original long-axis. The results indicated that bone-implant interfacial micro-motion was reduced and a favorable stress distribution after osseointegration was achieved.

These are exciting results and it seems inevitable that with continued advances in additive manufacturing (i.e. 3d printing), patient specific implants will emerge as a common treatment protocol in the not too distant future. What are your thoughts on custom made implant designs? Hype or future reality?

1\. Comput Methods Biomech Biomed Engin. 2017 Jan 29: [Influence of custom-made implant designs on the biomechanical performance for the case of immediate post-extraction placement in the maxillary esthetic zone: a finite element analysis.](https://www.ncbi.nlm.nih.gov/pubmed/28132525) Chen J et al.