On May 11, 2010, a periodontist placed a one stage implant of #30, just 3 days after flap surgery in the immediate area to the end of the right mandible. The pain was/is unending, day and night causing sleep deprivation. He dismisses the pain, tells the patient to take pain killers and refers the patient to oral surgeons at the dental school he taught at. The periondontist refuses to remove it, insisting he has done thousands of implants for 25 years and nothing is wrong with it.

The patient(me), goes to his first referral June 17, before Osseo integration takes place. She gets the "everything is normal," no reason for pain, letter. The patient, in excellent health, does not take, or tolerate any meds/ drugs, maintains a healthy balanced diet and outdoor lifestyle. The oral surgeon wants to prescribe a daily medication for the masseter muscle, that he insists is the cause of pain. The patient refuses the prescription.

Still in excruciating pain, the patient again requests implant removal, is dismissed with another referral, to another "titled" oral surgeon, at the same teaching hospital.

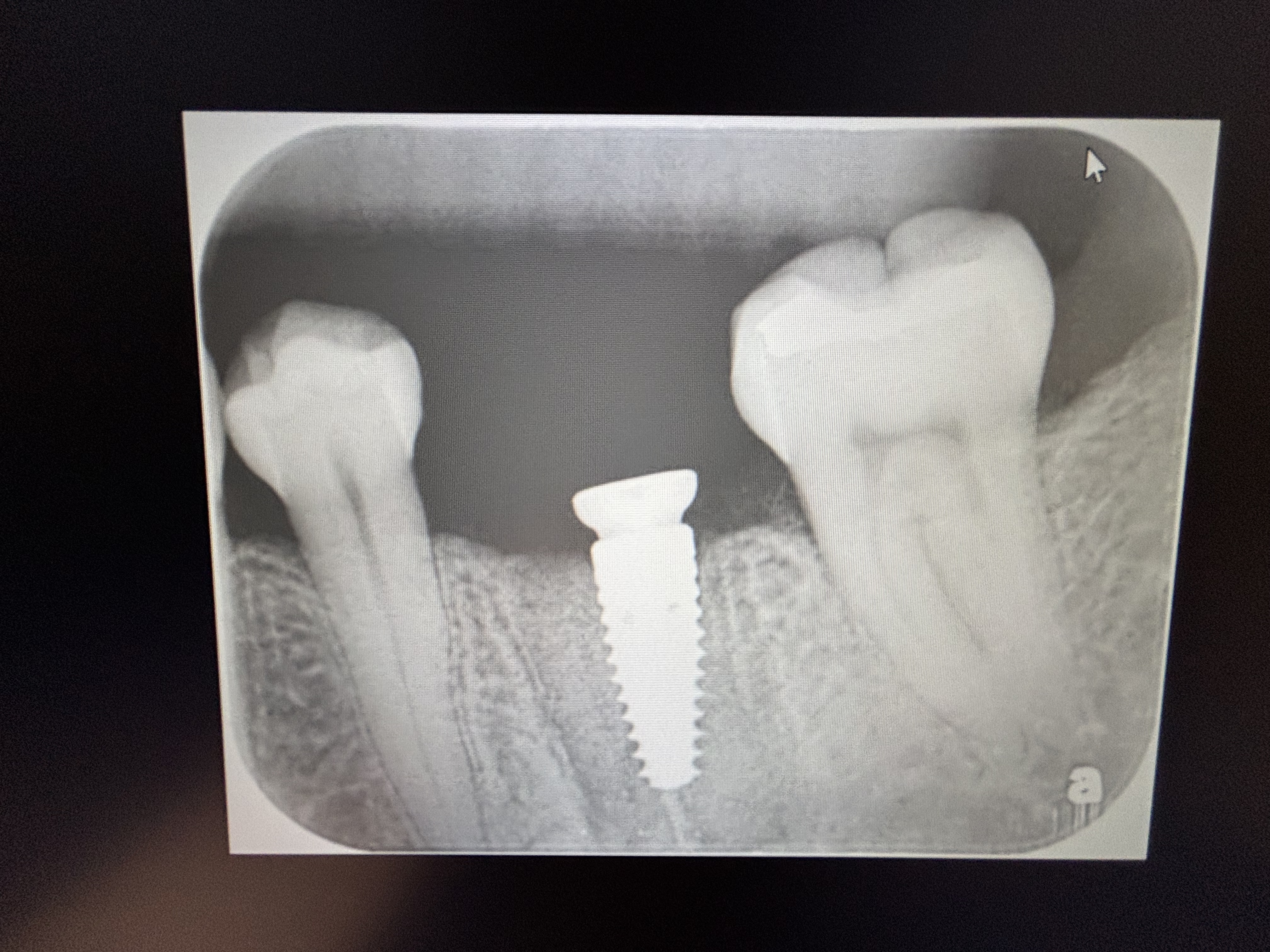

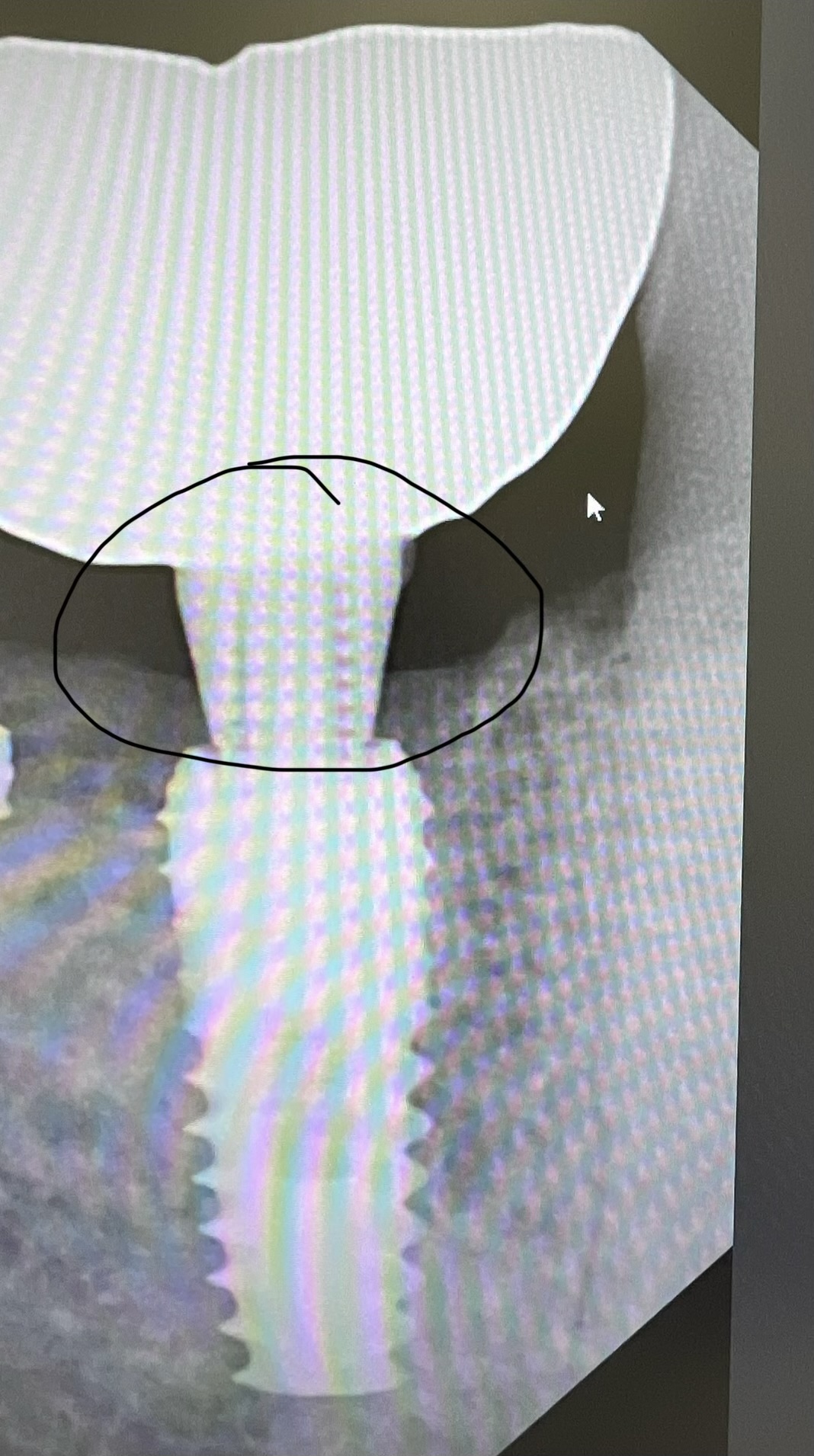

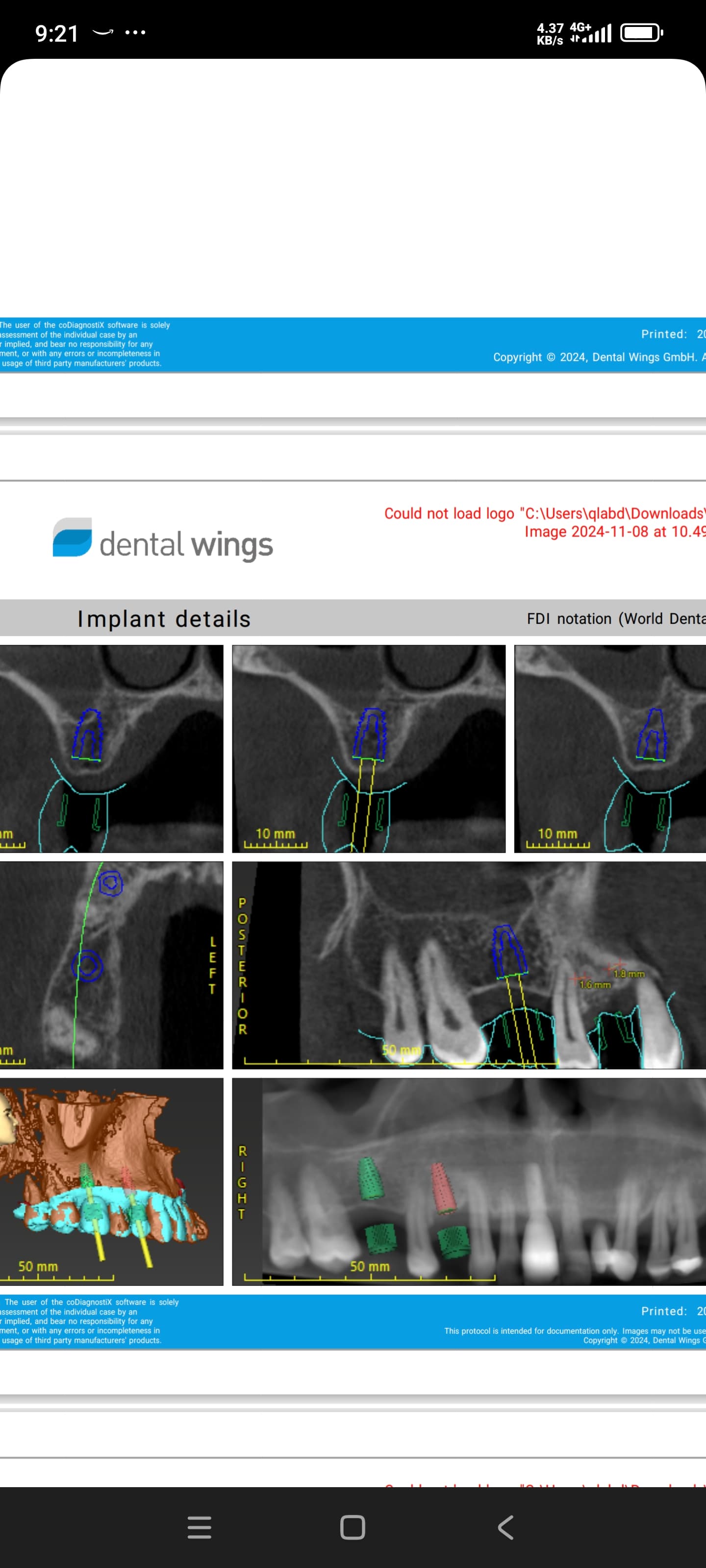

Patient remains "bone shivering pain" and insists on implant #30 removal. August 23, the implant periondontist takes another x-ray, insisting it looks great, and his implant record of thousands in 25 years, is perfect. The patient again, describing the compression pain and how it radiates to the end of the right mandible from under #30. It feels like its at a compound angle, leaning towards 29, and the tongue, it cannot bear the slightest pressure/compression, either from tongue or a piece of lettuce, touching it. He then applies 45n torque, telling the patient she is not qualified to diagnose any implant problems.

Dr. removes the screw and replaces it with a thin screw cover, below the gum line. Insists patient see his second referral and dismisses his patient, saying he can do nothing more for her.

Since the small screw replacement, the pain diminished, and the patient can sleep more than an hour or two, without ice. There is still an implant presence, with creepy invasive, claw tugging, discomfort. The 30 area cannot tolerate the slightest pressure, from a fallen piece of soft food. The patient informed the implant periodontist, that implant #30, could never be load bearing.

Now the patient is stuck with an imbedded piece of Titanium, that will never hold a crown and a dentist who refuses to remove it.