I’m assuming it had fractured at this point and based off of what appears to be cement at the platform, it was simply recemented as I’m sure his access to implant services were limited in Afghanistan. Obviously my first point of attack will be to retrieve the fractured piece of abutment and restore from there with a temporary crown to reestablish gingival contour, followed by a final restoration. I was wondering if anyone has experienced this before or could offer some advice as to how to retrieve the fractured abutment. With the fact that it is basically tapped into place and not threaded, I’m concerned that conventional broken screw retrieval methods may not work. Anyways I appreciate your feedback immensely."

***********************************************************

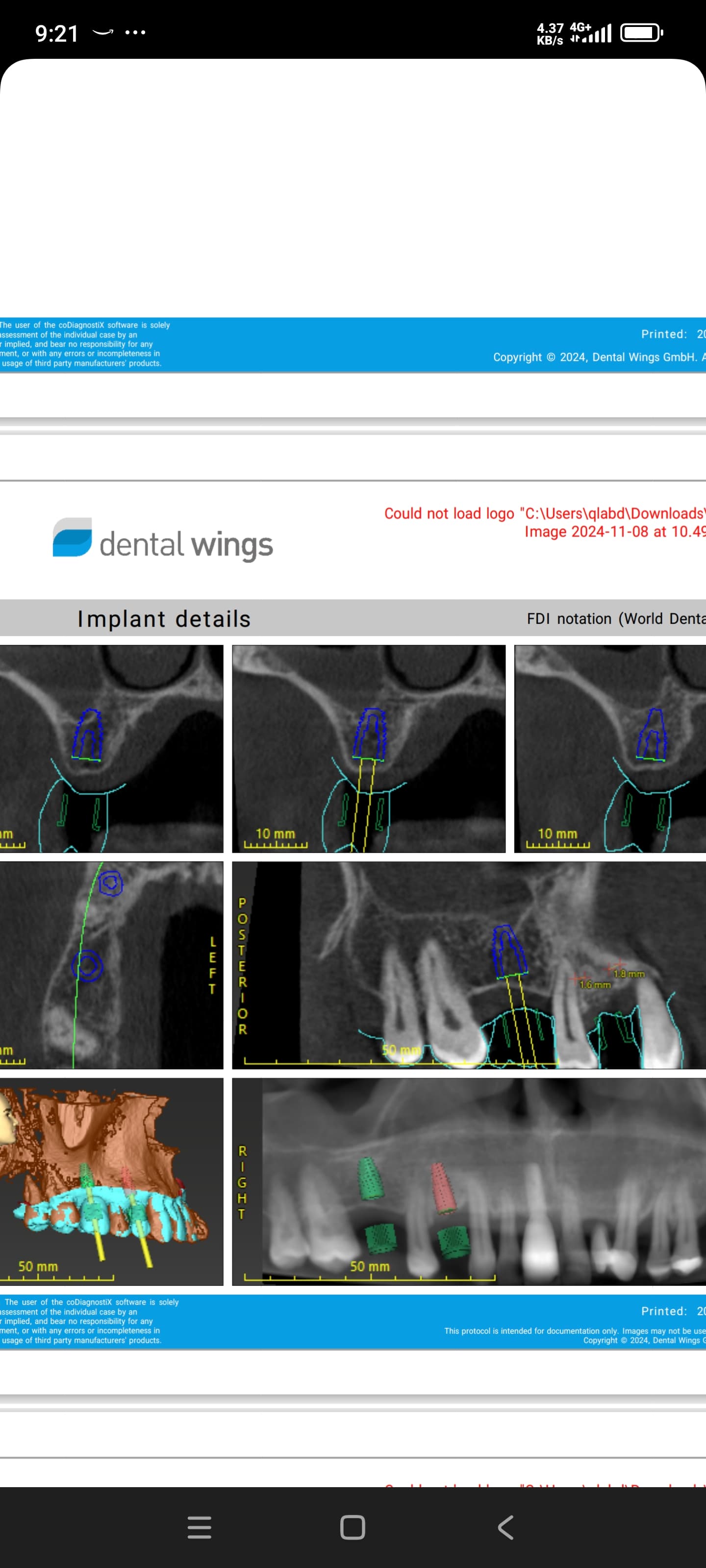

Is that the radiograph & the photo of the corresponding crown/fractured-post??????

*********************************************************

1. You may, please be assured, that

You already have the skills to resolve it... post a photo.

I would, Practice an OCCLUSAL CAVITY preps (not on tooth), at least 5-10 of them.

Create 1/2 a dozen holes of 1.5x2.0mm diameter using a SS spoon handle.

How you do it:

A permanent ink RED/BLACK circle of 2.5mm diameter marked on the handle.

Any selection of your CHOICE of tool and material that you feel comfortable with.

Example; 1/4, 1, 1/2 2mm dia: Carbon, steel, (diamond), tungsten, FG, Latch

MUST, GAIN CONTROL on PREVENTING HEAT GENERATION... easy

Must GAIN CONTROL from SKIDDING....hard, this comes from GAINING CONTROL ON amount of PRESSURE APPLIED...easier, also DEPENDS UPON "RPM" .... easy.

1. Be it one hour TEN or TWENTY HOURS it takes/took

2. Be it 1, 2 or TWENTY INSTRUMENTS that BROKE ,

3. TWO most important FACTORS TO "SUCCEED" IN THE PROCESS, IS being able to

RECOGNISE(A) and RESOLVE(B) as follows

A. WHY is that particular, METHOD, MATERIAL, TOOL or TECHNIQUE used is

NOT working as INTENDED and then, ask/seek help, if necessary

B. WHAT WOULD BE SPECIFIC SOLUTIONS, or (exposing) the secret, or the MAGIC

THAT WORKS in that so called SKILLED HANDS!!!!!!!!!

I am not dare enough to go in the patient's mouth until I gain my skills to put that hole in that SPOON HANDLE as PRESCRIBED for myself!

I have shared my method of gaining skills required of me whenever challenged .

I will be

Upon successfully creating a 1.5-2.00mm hole in 2.5mm circle, with a 0.25mm wide INTACT & UN-SCRATCHED margin of the circle... you would have CONQUERED

2. You will never, ever, find any screw, any where, in or around the implant,

for you to find it in the first place and let alone "retrieve" it!!!

3. You might consider posting

an intra-oral photo, for evaluation of "perio-implant complex"

4. At this point, it appears, that what is appropriate would/could be as simple as

A. Selecting an abutment that "accommodates" AESTHETIC REQUIREMENTS and

B. Fabricate a crown, either in one piece, OR cemented outside the mouth.

C. Making sure, that the emergence profile of this crown (360degree) be perfect.

Perfect, in terms of, (a) aesthetics; (b) emergence profile and (c) biological demands

D. Making sure, at the time of delivery, that the occlusion/occlusal contacts in

i. centric; ii. protrusive & iii. lateral excercussions be "CLEARLY CLEARED"

5. The cement you are referring to, is not over the implant platform... I don't see any.

it is stuck to, or over the emergence profile, contours of the crown,,, is it?

6. These bicon implant's platforms have NO opportunity to put-up with any cements!

Note/suggestion:

Best of results for steps, at A, B, C and D from above, could be easily achieved, by providing a custom provisional crown... and

It would be, at that point, easiest for the lab to simply DUPLICATE the final crown.

You may consider utilising this existing abutment for fabricating a custom provisional (PMMA) crown. But, this abutment-base's configuration seems to be quite in-appropriate. Because, it may not allow sculpturing and achieving targeted crown contours.

Comments, suggestions and constructive criticism welcome.

[email protected]