Gerald Niznick

OsseoNews(ON): You began a decade-long search in the early 1970s for a more effective dental implant. What spurred you to undertake it, and how did your research process work?

Dr. Niznick: Being a Prosthodontist, I had a great deal of success with overdentures retained by a few remaining lower anterior teeth. Typically, these compromised remaining teeth were treated endodontically, cut down to reduce the lateral forces and either joined by a gold bar, had Zest anchors cemented. By the end of the 1970’s, being somewhat disappointed with predictability and invasiveness of subperiosteal implants, I developed the Core-Vent implant that could accept a cemented post that could function free-standing with an overdenture attachment, which I called the Core-Vent Attachment. It became evident that the only way this would work was if the implant became anchylosed, and to achieve this, I needed to avoid overheating the bone during insertion and avoid early loading, which lead me to bury the implant for a few months. To enhance the prosthetic versatility of the implant, I created a deep hex hole for a wrench-engaging surface and for subsequent cementation of a variety of prosthetic abutments for specific restorative applications, cemented crowns, screw-retained bars and snap-on attachments. The abutments for cemented restorations were offered in bendable and castable versions to accommodate parallelism and esthetics. That was the start of the modern era of versatile implant prosthodontics with osseointegrated (anchylosed) implants.ON: Your 20 patents make you a highly successful inventor. How have you handled the technical aspects of both product development/testing, and of patent prosecution?Dr. Niznick: Many inventions represent technology for technology’s sake and do not solve or contribute to the solution of real clinical problems. The Core-Vent implant had a hex hole for cemented abutments. While this added versatility to the prosthetic applications, it was at the expense of irretrievability and also relied on the dentist fully seating the abutment and cleaning the cement. Taking that same Hex hole and adding internal threads, gave the implant abutment connection irretrievability. It also solved some other problems that external hex implants of the time had, like increases stability, increased tactile sense all in a narrower platform than was common with the Branemark Implant, eliminated the need for X-rays following abutment attachment. The FDA mandates a series of bench tests for evaluating strength such as torque tests, bending tests and cyclic loading. The wide use of the Core-Vent in the hands of non-surgical specialists proved its clinical success and acceptance. The internal connection has been licensed to about 9 companies and has now become the industry standard. Patent litigation is time-consuming and expensive, but necessary to protect one’s proprietary interests. Patents are not usually filed for small countries such as Israel, and as a result, several small companies sprung up cloning the design of the Screw-Vent. Zimmer has licenses BioHorizons and 3i since acquiring the patent from me in 2001. I have since filed 9 new patents and am looking forward to introducing new designs that build on the success of not only my previous ones, but also incorporate the best features of some of the major implant companies.ON: When you established Core-Vent Corp. in 1982 to produce and market your new implant, did you have previous business experience? How did your expertise in managing the company evolve?Dr. Niznick: I was in full time practice of prosthetics when I first introduced the Core-Vent. I could not get anyone to distribute it for me so I just started selling one and two-day implant courses and the sale of the implants became a by-product of those educational courses. The demand for implant education was tremendous in the 1980’s. It was not unusual for me to give a one-day lecture with two-hundred registrants and have another 100 walk-ins. My company started to grow at about 25 people a year and I was traveling about half the time lecturing around the world and establishing distributors. I had a very loyal and enthusiastic cadre of young people working for me, who were excited about being part of a revolution in dentistry. Their dedication allowed me to focus on product development and education. My family was also very supportive and I developed a circle of professional colleagues, who started to carry the ball by giving two-day live surgical courses at teaching centers around the world.ON: How difficult was it to combat patent infringement against the Core-Vent System? Did you personally play a major role in the ongoing litigation and licensing processes?Dr. Niznick: The only company to infringe the Core-Vent Patent was Straumann in the early 1990’s when they also combined the basket with threads in what they called the Bonfit System. After a one-week trial to a jury, they were found to infringe and subsequently were enjoined from selling in the US for 6 months until they took a license. After the introduction of the Screw-Vent in 1986, a number of companies saw the advantage of this design and introduced implants that infringed. A number of the smaller ones were stopped and a few of the larger ones took licenses. As 100% owner of Core-Vent Corp, and then Paragon Implant Company, I was very personally involved in patent litigation and licensing of my inventions.ON: What led to your 2001 decision to sell your implant business to Sulzer Medical?Dr. Niznick: After 20 years in the implant business, and with only 7 years remaining on the Internal Connection Patent, it seemed like the right time to retire. Calcitek (Sulzer) desperately needed my manufacturing facility and product developments. Lets say they made me an offer I could not refuse..ON: When you became CEO of Acromil, you had to transform the culture of an existing company in an industry (aerospace) that was new to you. What were your biggest challenges, and how did you develop and

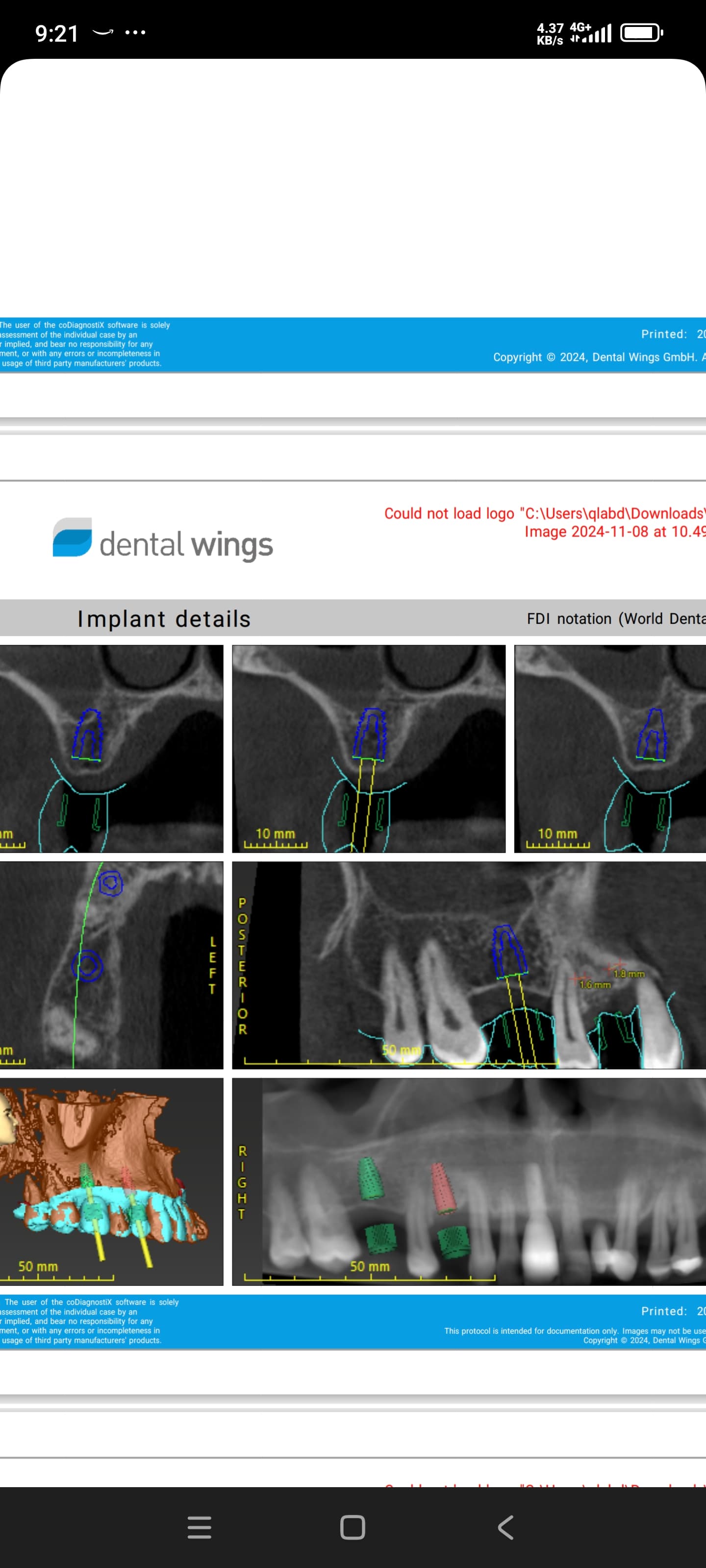

implement your leadership strategy?Dr. Niznick: Acromil is an aerospace manufacturing company that I bought 3 years ago, partly because of my love for aviation, and partly because the company was in financial trouble and I was able to buy it for about the price of the real estate. Making large structural parts for aircraft, some as long as 40 feet is a world away from making dental implants that are about 1/2 inch long.. After 3 years and millions in additional investments in new equipment and expansion of the facility to 100,000 sq. ft, we have gained the industry respect that is necessary to win large contracts for military and commercial aircraft. My function is not on a technical level but to hire and empower qualified people and then give them the support and resources they need to do their job. Because work goes to the lowest bidder in this industry, with a markup of only 10% if you have bid the job right, too many small companies underbid to get the jobs because they need the cash flow to exist. This becomes a fatal cycle so the large aircraft companies, like Boeing, Lockheed, Israeli Air Industries, Northrop are looking for manufactures with staying power and deep pockets. The dental implant business gave me the ability to survive our early mistakes and become profitable and credible in a very difficult industry. .ON: Your new implant venture would appear to be revolutionary in its product technology. Could you generally discuss how you developed the idea for this new approach?Dr. Niznick: While I can’t talk specifically about the designs of my new implants as I am under a non-compete with Zimmer dental until January 8, 2006, I will say that designing a “clean sheet” system with no old parts or marketing positions to lock me in was a great experience. It gave me the opportunity to approach implant development from a different standpoint. I call it Application Specific Implants, where each implant has a specific clinical application and each implant includes a prosthetic abutment for that application. All six of my implants will be able to be inserted with the same set of drills making it truly universal. With the move towards one-stage surgery and immediate loading, 3 of the 6 implants are one-piece implants for various prosthetic and clinical situations, saving the dentist the cost of having to buy additional components. The two-piece implants are all provided in fixture mounts that can be modified to be a final abutment also.ON: Press reports indicate that you will be marketing your new implant technology directly to dentists through the Internet. Could you generally discuss how you will undertake this ground-breaking marketing effort?Dr. Niznick: Having run Paragon Implant Company with 260 employees prior to selling to Centerpulse/Zimmer, I wanted to avoid the whole sales force/opinion leader method of selling dental implants that accounts for about 50% of Nobel’s and Straumann’s overhead. I believe in the Dell philosophy of selling direct and will have a very intuitive web site that explains the features, benefits and advantages of my new designs by direct comparisons to the competitor’s products. We will be able to provide technical support on-line by instant chat responses. I will be able to offer the highest quality products at substantial discounts over the major companies’s prices, while maintaining a wide selection and complete inventory. I will take advantage of Internet sales with no receivables, consignment inventories, exchange guarantees, etc. This is for those dentists who know what they are doing and know what they want. I was fortunate to re-acquire my factory that I build in 1994 and to rehire 50+ of my former manufacturing people after Zimmer decided to move to new and larger facilities in the San Diego area. Starting fresh with all new machines, and employing new technology that will allows lights out for 16 hours following a normal day shift. This is accomplished by installing vibration and power sensors on every machine to detect tool wear, and then rotate in a new tool when it starts to wear. From our web site, four video camera’s will show the untra-modern facility and production floor. I will have invested $15,000,000 before I sell my first product. No small company trying to make a low priced implant could ever dream of launching the wide selection of implant designs and prosthetic components, targeted against, and in some cases, compatible with every major implant design. What I bring that is new to the industry, is the pricing of the small companies with the quality, inventory and selection of the big companies. Also, designs that incorporate the best features, as I see them, of all systems. With 8 new patents on file, representing features incorporated into the new system, and the manufacturing capabilities that only come from having an experienced team with an average of 10 years in the implant industry, I am excited to be able to further contribute to the professional acceptance and success of dental implants.ON: You are an inventor, entrepreneur and educator as well as a medical professional. Has any one role given you greater personal satisfaction, or do you view all your work as a unified whole?Dr. Niznick: I am an clinician first and needed the inventions to implement my treatment philosophies,. I needed to be an educator and entrepreneur to have the financial resources to see my inventions become clinical realities and to advance the field of implant dentistry.ON: What are we going to see in the next five years in Implant innovation and what are some of the most important concepts that dentists should be thinking about?Dr. Niznick: As far as implant designs go, you will have to wait until January 8, 2006 to see the answer to that question. I would have to say that my new system will be a quantum leap forward in the concept of application specific implants with multi-functional components and simplified prosthetics, for both economy and ease of use. As far as what I see in the next five years, it is increased ease and accuracy of placement of dental implants, thus expanding the insertion by more general practitioners through image guided placement and I have invested in an Israeli Research Team to help bring this about.